Surface mount technology shapes the electronics industry by allowing smt assembly of tiny components directly onto circuit boards. The use of smt technology boosts production efficiency by up to 30% and enables miniaturization, with components as small as 0.4 mm x 0.2 mm.

| Aspect | Numerical Data | Impact Description |

|---|---|---|

| Production Efficiency | Up to 30% improvement | Automation in smt assembly lines increases production yields and reduces labor costs. |

| Component Size for Miniaturization | Components as small as 0.4 mm x 0.2 mm (01005 size) | Drives device miniaturization in smartphones and wearables. |

| Quality Control Optimization | Machine learning-enabled frameworks | Improves manufacturing quality in smt assembly. |

Surface mount technology drives smt assembly in smartphones, cars, and medical devices. The global market for smt assembly reached USD 6,251.6 million in 2024 and will likely grow to USD 9,594.2 million by 2032.

| Metric/Aspect | Value/Trend | Year/Period |

|---|---|---|

| Global SMT Market Size | USD 6,251.6 million | 2024 |

| Projected Market Size | USD 9,594.2 million | 2032 (forecast) |

| SMT Market Share (Overall) | 55% | 2024 |

| SMT Market Share (Projected) | 57% | 2025 |

Smt assembly supports the fast production of reliable electronics, making it essential for everyday devices.

Key Takeaways

-

Surface mount technology (SMT) makes things faster by 30%.

-

It lets us use small, exact parts for tiny, smart gadgets.

-

SMT helps important fields like electronics, cars, and medicine.

-

It also helps factories and phone companies make strong, small products.

-

Machines and smart tools like AI cameras check for mistakes in SMT.

-

These tools help make better products with fewer errors.

-

Good SMT work needs careful glue, right part placement, and strong checks.

-

Doing these steps well makes SMT faster and products last longer.

-

In the future, SMT will use even smaller parts and smarter machines.

-

New materials and earth-friendly ways will make better electronics.

Principles of SMT technology

How surface mount technology works

Surface mount technology (SMT) revolutionized electronics manufacturing by enabling the direct placement of components onto the surface of printed circuit boards (PCBs). Unlike traditional through-hole methods, SMT eliminates the need for drilling holes, allowing for smaller, lighter, and more complex designs.

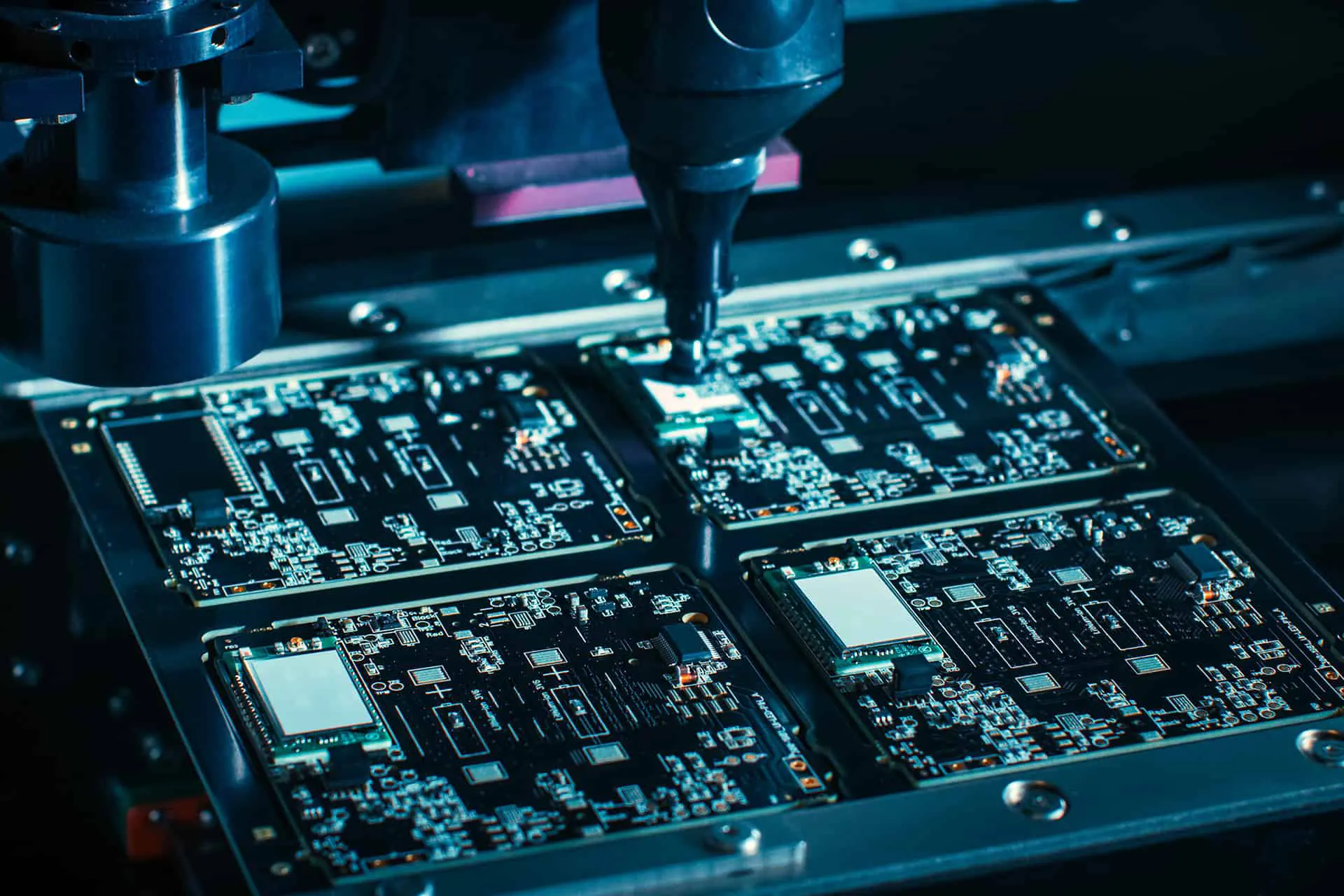

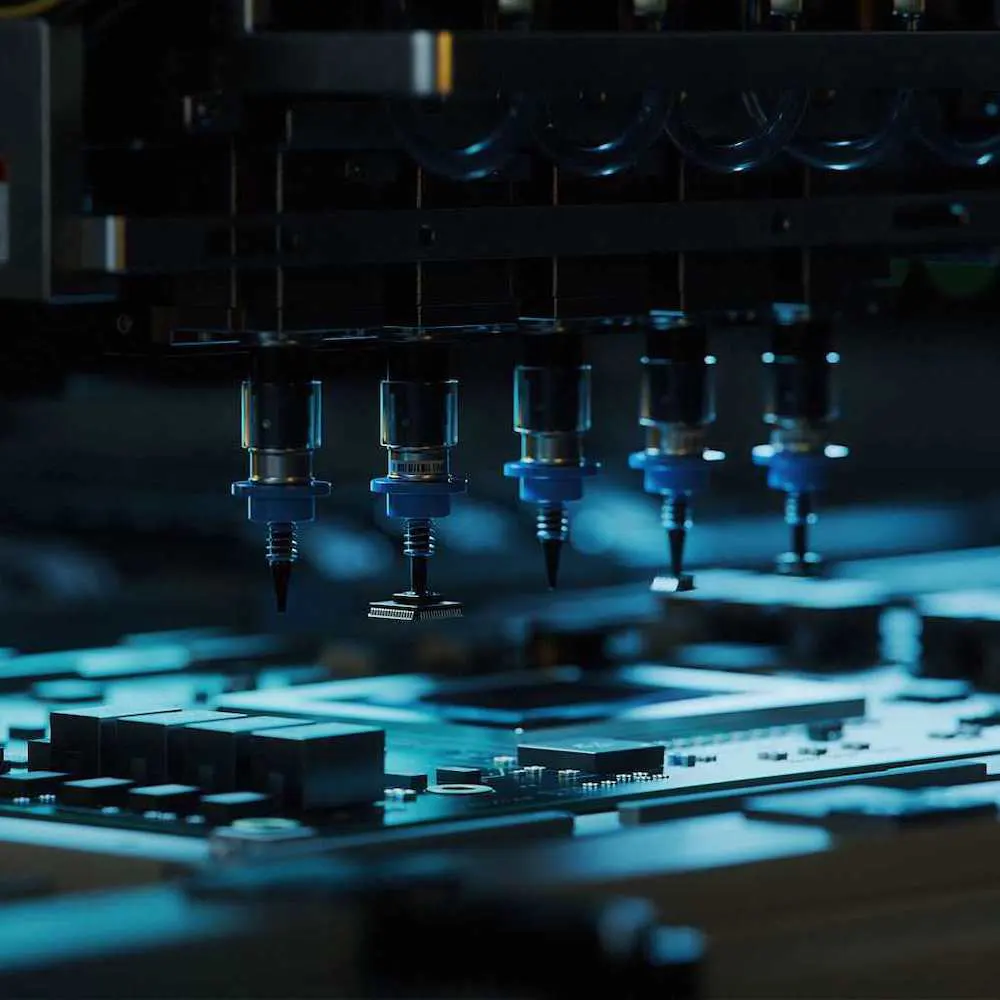

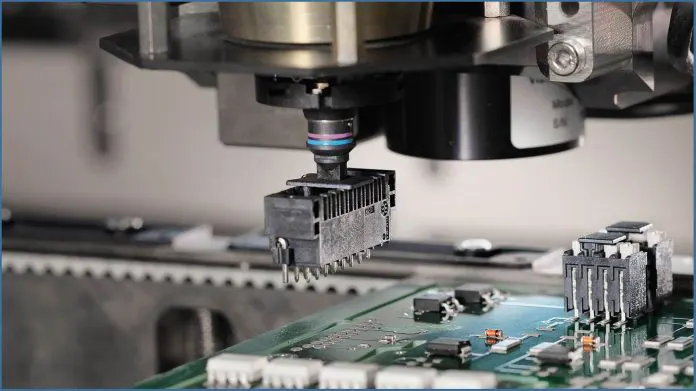

The process begins with the application of solder paste onto the PCB using a stencil. This paste acts as an adhesive and electrical connection medium. Automated pick-and-place machines then position surface-mount components (SMCs) onto the solder paste with remarkable precision, achieving placement accuracy of up to ±10 microns. Once all components are in place, the assembly undergoes reflow soldering, where controlled heat melts the solder paste, forming secure electrical connections.

Inspection plays a critical role in ensuring quality. Automated Optical Inspection (AOI) systems detect defects as small as 10 microns, while X-ray inspection verifies hidden solder joints. These steps ensure that SMT assembly produces reliable and high-density PCBs for modern electronics.

Tip: SMT's ability to handle components as small as 0.4 mm x 0.2 mm makes it indispensable for miniaturized devices like smartphones and wearables.

Key components in surface-mount technology

Surface-mount technology relies on a variety of components, each designed for specific functions. Common surface-mount components include:

-

Resistors and capacitors: Available in sizes like 0402, 0603, and 0805, these components regulate current and store energy.

-

Integrated circuits (ICs): These include microcontrollers, processors, and memory chips, forming the brains of electronic devices.

-

Diodes and transistors: Essential for controlling current flow and amplifying signals.

-

Inductors: Used in power supplies and radio-frequency circuits to store energy in magnetic fields.

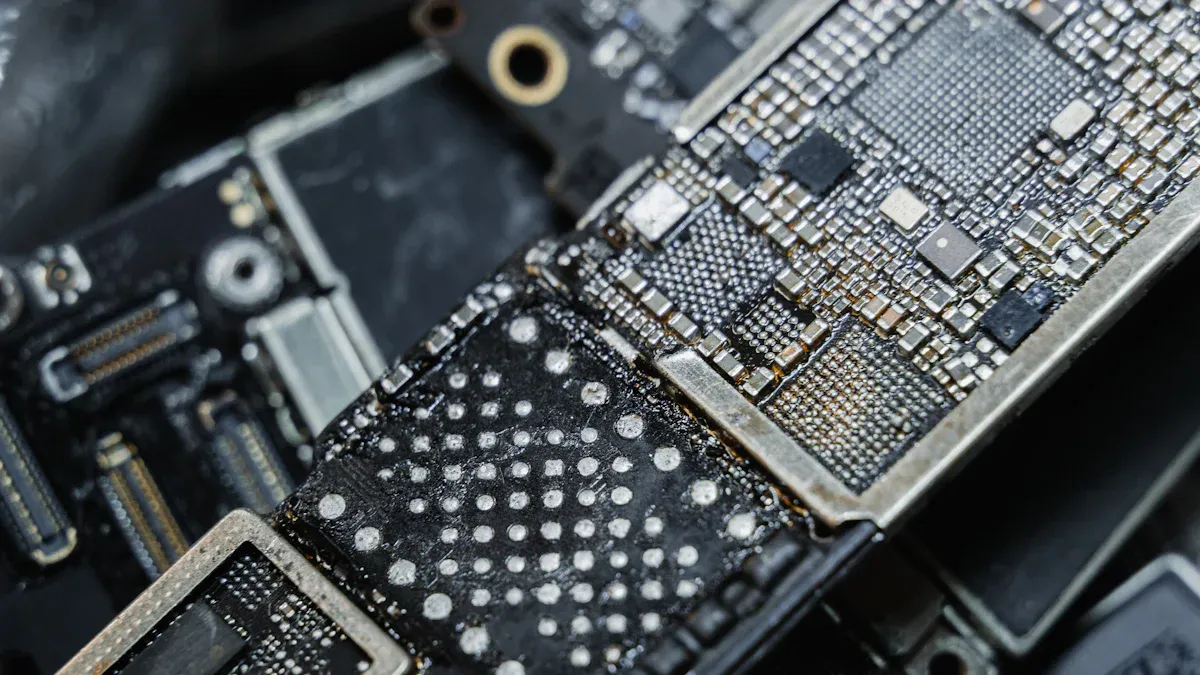

Advanced PCB technologies, such as High-Density Interconnects (HDI), further enhance SMT by incorporating microvias, buried vias, and blind vias. These features increase component density without enlarging the PCB size. High-performance materials like FR4 High-Tg and polyimide ensure durability under thermal and mechanical stress.

Note: Proper component orientation, especially for polarized components like diodes, is crucial to prevent functional errors during SMT assembly.

SMT assembly process overview

The SMT assembly process involves several well-defined steps to ensure precision and reliability:

-

Solder Paste Printing**:** A stencil aligns with the PCB to apply solder paste accurately. Stencil printers achieve alignment accuracy within ±25 microns.

-

Component Placement: Pick-and-place machines position components based on design specifications. Vision systems ensure correct alignment and orientation.

-

Reflow Soldering: The assembly passes through a reflow oven, where controlled temperatures (±2°C) melt the solder paste, forming strong connections.

-

Inspection: Automated Optical Inspection (AOI) and X-ray systems detect misalignments, solder defects, and other issues.

-

Final Testing: Functional tests verify that the PCB meets design and electrical specifications.

Thermal management techniques, such as heat sinks and thermal vias, play a vital role in maintaining component reliability during operation. Additionally, detailed documentation ensures traceability and simplifies future maintenance.

Callout: Following PCB design rules, such as maintaining optimal spacing and grouping related components, enhances signal integrity and reduces interference.

Applications of surface mount technology

Surface-mount technology has transformed the electronics industry by enabling efficient, reliable, and compact smt assembly across a wide range of sectors. The following sections explore the most significant applications, highlighting how smt assembly supports innovation and performance in consumer electronics, automotive systems, and medical devices.

Consumer electronics and SMT assembly

Consumer electronics represent one of the largest and fastest-growing applications for surface-mount technology. Devices such as smartphones, tablets, laptops, and wearables rely on smt assembly to achieve compact designs, high functionality, and rapid production cycles. Manufacturers use advanced placement equipment and next-generation inspection systems to meet the demands of this competitive market.

Key performance metrics in consumer electronics smt assembly include:

| Metric | Value (2023) | Projection (2031) | CAGR (2024-2031) |

|---|---|---|---|

| SMT Assembly Line Market Size | USD 5,801.12 Million | USD 10,160.00 Million | 7.29% |

| Market Volume (Units) | 6,212 Units | 9,406 Units | 5.37% |

| Consumer Electronics Market Share | 35.88% | N/A | 8.94% |

| Consumer Electronics Market Value | USD 2,081.46 Million | N/A | 8.94% |

| High-Speed SMT Lines Market Value | USD 2,707.03 Million | N/A | 8.50% |

| Fully Automated SMT Lines Market Value | USD 4,178.03 Million | N/A | 7.93% |

| In-line Layout Market Value | USD 2,772.42 Million | N/A | 8.57% |

| Asia Pacific Market Share (2031) | N/A | 55.21% | 8.16% |

Manufacturers focus on improving first pass yield, reducing defect rates, and shortening cycle times. These efforts result in reliable products and lower production costs. The Asia-Pacific region leads in market share, driven by a strong electronics manufacturing base and skilled labor. Companies invest in high-speed and fully automated smt assembly lines to keep up with demand and maintain quality.

Tip: High-performance devices like smartphones and smartwatches depend on the miniaturization and precision offered by surface-mount technology.

Automotive industry and surface-mount technology

The automotive sector has seen rapid growth in the adoption of surface-mount technology, especially with the rise of electric vehicles and advanced driver-assistance systems (ADAS). SMT assembly enables the production of complex electronic modules, including engine control units, infotainment systems, and battery management systems.

Recent trends in automotive smt assembly include:

-

Global SMT equipment shipments reached 6,212 assembly lines in 2023, reflecting increased production capacity.

-

Placement equipment accounted for 59% of equipment volume, showing a focus on precision assembly.

-

High-speed SMT lines made up 46.66% of shipments, emphasizing throughput.

-

AI-driven Automated Optical Inspection (AOI) adoption surged by 44% in 2023, with over 56% of U.S. electronics manufacturers using AI-based AOI.

-

52% of new AOI installations target automotive, medical, and aerospace electronics.

-

China’s vehicle production reached over 30 million units in 2023, a 12% increase, driving demand for SMT lines.

-

Nearly 14 million new electric cars were registered globally in 2023, a 35% year-on-year increase, boosting SMT demand in automotive module assembly.

Automotive manufacturers benefit from smt assembly by reducing printed circuit boards drilling requirements, saving time and costs, and enabling higher component density. Improved signal integrity and electrical performance result from shorter connection paths. Companies like Continental Device India Limited and Hyve Solutions Corporation have invested in advanced smt assembly lines to support the production of sophisticated automotive-grade devices.

Note: The automotive industry relies on surface-mount technology to achieve the reliability and miniaturization required for modern vehicle electronics.

Medical devices using SMT technology

Medical devices demand the highest standards of reliability, safety, and regulatory compliance. Surface-mount technology plays a crucial role in the smt assembly of medical electronics, from wearable monitors to implantable devices and diagnostic equipment.

Manufacturers follow strict regulatory frameworks, such as FDA oversight and ISO 13485 certification, to ensure device safety and performance. The smt assembly process for medical devices includes:

-

Detailed design and component sourcing from certified suppliers.

-

SMT assembly in cleanroom environments to minimize contamination.

-

Rigorous quality control, including electrical safety, functional, and environmental testing.

-

Compliance with standards like FDA CFR Title 21, ISO 13485, and ISO 14971 for risk management.

Reliability is critical because failures in medical devices can be life-threatening. Printed circuit boards for medical applications must withstand harsh conditions, such as temperature changes, humidity, vibration, and electrical noise. Manufacturers use automatic optical inspection and advanced testing to detect defects early and ensure consistent performance.

Callout: Emerging trends like advanced automation and cleanroom smt assembly further enhance manufacturing precision and reduce defects in medical electronics.

The use of surface-mount technology in medical devices supports miniaturization, power and thermal management, and signal integrity. Collaboration with knowledgeable suppliers and adherence to international standards ensure that medical electronics meet the highest levels of reliability and safety.

Industrial equipment and SMT assembly

Industrial equipment relies on surface-mount technology to achieve high reliability and efficiency in demanding environments. SMT assembly supports the production of control systems, power modules, sensors, and automation devices. These applications require robust performance, long operational life, and resistance to harsh conditions such as vibration, temperature changes, and electrical noise.

Manufacturers use smt assembly to increase production speed and reduce manual labor. Automated pick-and-place machines and reflow ovens streamline the process. The use of surface-mount technology allows for compact designs and high component density, which are essential for modern industrial equipment.

Production efficiency and defect rates play a critical role in industrial smt assembly. The following table summarizes key performance metrics from a sample of 100 SMT lines:

| Metric | OEM Sample (28 SMT lines) | Contract Manufacturers (72 SMT lines) | Overall Sample (100 SMT lines) |

|---|---|---|---|

| Average Line Efficiency | 46% | 54% | 52% |

| Staffed Time per Week | 101 hours | 112 hours | N/A |

| Pick-and-Place Machine Time | 45 hours | 63 hours | N/A |

| Yearly Assembly Volume per Operator/Inspector | 4.4 million components | 4.7 million components | 4.6 million components |

| World-Class Line Efficiency | ~65% or higher (factory avg) | N/A | N/A |

| High-Volume Line Efficiency | >80% | N/A | N/A |

| High-Mix Line Efficiency | ~60% | N/A | N/A |

Contract manufacturers often achieve higher efficiency than original equipment manufacturers. World-class SMT lines can reach 65% efficiency or more, while high-volume lines may exceed 80%. Each operator or inspector can handle about 4.6 million components per year, showing the scale of modern smt assembly.

Automated Optical Inspection (AOI) systems play a vital role in quality control for industrial applications. AOI uses high-resolution cameras and image processing to detect issues such as missing components, misalignment, and soldering defects. These systems improve inspection speed and accuracy, reduce human error, and help manufacturers identify problems early. AOI also generates detailed reports and analytics, which support continuous improvement in smt assembly.

Tip: AOI not only reduces defect rates but also lowers maintenance costs and waste, making it a key technology for industrial equipment manufacturers.

Industrial applications of surface-mount technology include programmable logic controllers (PLCs), motor drives, robotics, and factory automation systems. SMT assembly enables these devices to operate reliably in challenging conditions, supporting the growth of smart factories and Industry 4.0 initiatives.

Telecommunications and surface mount technology

Telecommunications equipment depends on surface-mount technology to deliver high-speed, reliable, and compact solutions. SMT assembly supports the production of routers, switches, base stations, and network interface devices. These applications require precise signal integrity, low power consumption, and the ability to handle large data volumes.

The demand for advanced telecommunications devices continues to grow with the expansion of 5G networks, the Internet of Things (IoT), and cloud computing. SMT assembly enables manufacturers to meet these demands by allowing for miniaturization and high-density circuit designs.

The market for SMT inspection equipment reflects the increasing complexity of telecommunications applications. The SMT inspection equipment market is expected to grow from USD 885 million in 2023 to USD 1.65 billion by 2032. This growth is driven by the need for precision, the adoption of AI and machine learning in inspection, and the rise of IoT devices. Asia Pacific leads in manufacturing, while North America and Europe see growth in aerospace, defense, and telecommunications sectors.

Telecommunications companies benefit from several technological advances in smt assembly:

-

AI-enabled placement systems improve accuracy and speed.

-

Automation and digital twins optimize production processes.

-

Modular equipment allows for flexible manufacturing.

-

Advanced AOI ensures high quality and reliability.

| Aspect | Details |

|---|---|

| End-User Industry | Telecommunications companies included as a key segment, indicating SMT's relevance in telecom device manufacturing |

| Technological Advances | AI-enabled placement systems, automation, digital twins, and modular equipment improving production efficiency and quality |

| Market Trends | Growth pockets identified in telecommunications sector; tariff impacts influencing sourcing and cost strategies |

| Regional Insights | Emphasis on localized manufacturing hubs affecting supply chain resilience and cost structures |

| Competitive Dynamics | Mix of R&D-intensive incumbents and disruptors driving innovation in SMT placement equipment |

| Companies Covered | Includes major players like Beijing Huawei Silkroad Electronic Technology Co., Ltd., Panasonic Corporation, and others involved in SMT for telecom |

Manufacturers use smt assembly to produce telecommunications devices that meet strict quality and performance standards. Automated inspection methods, such as AOI, help ensure that each device functions correctly and reliably. The use of surface-mount technology in telecommunications supports rapid innovation, allowing companies to introduce new products quickly and respond to changing market needs.

Note: The combination of miniaturization, automation, and advanced inspection makes smt assembly essential for the future of telecommunications applications.

Challenges and best practices in SMT assembly

Common challenges in surface-mount technology

SMT assembly faces several recurring challenges that can impact product quality and reliability. Most defects occur during solder paste printing, component placement, and soldering. The following table summarizes the main issues and their effects:

| SMT Assembly Process Step | Common Challenges / Defects | Quality Metrics / Impact |

|---|---|---|

| Solder Paste Printing | Soldering balls, insufficient solder paste, irregular particle shapes | 70% of SMT quality defects start here |

| Placement (Chip Mounting) | Missing components, wrong orientation, misalignment | Highest defect rate among equipment |

| Soldering (Reflow) | Soldering balls, shorts, improper temperature | Directly affects performance and reliability |

Quality defects related to solder paste printing account for 60–90% of all manufacturing defects in smt assembly. Open solder joints, solder shorts, and component misalignment also contribute to failure rates. These problems can lead to costly rework and reduced product lifespan.

Careful control of each step in smt assembly helps reduce these common defects.

Quality control in SMT assembly

Effective quality control ensures that smt assembly produces reliable electronic products. Manufacturers use several tools and benchmarks to monitor and improve quality. Statistical Process Control (SPC) tracks process parameters and identifies trends. Defect analysis uses methods like fishbone diagrams and 5-Why analysis to find root causes. Automated Optical Inspection (AOI) and X-ray systems check for defects before and after soldering. Electrical testing, such as In-Circuit Testing (ICT) and functional testing, verifies circuit performance.

-

SPC software collects and analyzes data for smt assembly.

-

AOI systems inspect for missing or misaligned components.

-

X-ray inspection finds hidden soldering issues.

-

Regular audits and employee training support continuous improvement.

Tip: Combining automated inspection with regular testing increases the reliability of smt assembly.

Best practices for SMT implementation

Manufacturers follow best practices to optimize smt assembly and reduce defects. The following guidelines help achieve high efficiency and quality:

-

Streamline smt assembly with automation, such as pick-and-place machines.

-

Integrate optical inspection early to catch defects quickly.

-

Apply solder paste precisely using advanced stencil printing.

-

Standardize component sizes to minimize machine adjustments.

-

Collaborate with suppliers for consistent part quality.

-

Use AOI systems to verify placement and detect errors.

-

Control reflow soldering temperatures to prevent defects.

-

Maintain strict quality protocols and calibrate equipment regularly.

-

Train employees and encourage feedback for ongoing improvement.

-

Use rigorous testing, including AOI and ICT, to ensure product functionality.

Applying these best practices in smt assembly can reduce defect rates by 20% and boost productivity by 15%. Equipment upgrades, targeted inspection, and skilled operators play a key role in successful implementation.

Note: Continuous improvement and investment in technology keep smt assembly processes competitive and reliable.

Future trends in surface-mount technology

Miniaturization and high-density SMT assembly

Miniaturization continues to shape the future of smt assembly. Manufacturers now use advanced packaging methods like System-in-Package and Chip-on-Board to combine multiple functions in a single, compact unit. Nanoelectronics development allows for even smaller components, pushing the boundaries of what smt assembly can achieve. High-Density Interconnect PCBs, with features like microvias and fine-pitch components, support dense layouts without increasing board size. Liquid Crystal Polymer and polyimide substrates enable thinner, more flexible boards. These innovations help smt assembly meet the demands of consumer electronics, medical devices, and telecommunications.

Tip: 3D printing technology supports rapid prototyping and complex PCB designs, making smt assembly more adaptable for the future.

Automation and smart manufacturing in SMT technology

Automation drives the next wave of smt assembly. Automated pick-and-place machines and AI-powered inspection systems increase production speed and accuracy. Smart manufacturing uses digital tools like machine learning, digital twins, and big data analytics. These technologies enable predictive maintenance, real-time analytics, and adaptive control. Industry 4.0 principles help smt assembly lines become more efficient and reliable. Companies invest in automation to reduce labor costs and improve product quality. The integration of AI and robotics transforms smt assembly into a flexible, data-driven process.

-

AI and machine learning optimize defect detection.

-

Digital twins simulate and monitor operations in real time.

-

Predictive scheduling and fault prediction improve workflow.

Advanced materials and processes in surface mount technology

The future of smt assembly depends on new materials and processes. Lead-free, low-temperature solder alloys reduce thermal stress on small components. Fine-pitch packages and wafer-level designs allow for even greater miniaturization. High-density substrates support more connections in less space. Sustainability efforts focus on eco-friendly materials and waste reduction. The market for smt assembly equipment reflects these trends.

| Metric/Aspect | Data/Forecast |

|---|---|

| SMT Equipment Market Size (2025) | USD 11.5 billion |

| SMT Equipment Market Size (2030) | USD 15.16 billion |

| CAGR (2025-2030) | 5.67% |

| Key Growth Drivers | Miniaturization, automation, sustainability |

Smt assembly will continue to evolve as new innovations emerge. The future promises smaller, smarter, and more sustainable electronics.

Sustainability and eco-friendly SMT assembly

Sustainability in SMT assembly has become a critical focus as industries strive to minimize environmental impacts while meeting consumer demands for greener electronics. Companies now adopt eco-friendly practices that reduce waste, conserve energy, and optimize material usage throughout the product lifecycle.

Total Environmental Impact (TEI) and Life Cycle Assessment (LCA) methodologies validate these efforts by quantifying the environmental footprint of SMT assembly. TEI evaluates the entire lifecycle of a product, from design to disposal, emphasizing reductions in greenhouse gas emissions, water consumption, and waste generation. This approach supports certifications like EPEAT and Environmental Product Declarations (EPDs), ensuring that sustainability claims are credible and measurable. By integrating TEI into lifecycle management, manufacturers can select sustainable materials, conserve energy during production, and implement effective end-of-life strategies.

Material composition plays a significant role in the environmental impact of SMT assembly. Studies reveal that components containing precious metals, such as gold in SMD transistors, significantly increase environmental burdens. Gold content can amplify the impact of a transistor by up to 160 times compared to a reference model. To address this, manufacturers prioritize reducing critical raw materials and exploring alternatives like recyclable substrates and additive manufacturing techniques. These practices not only lower environmental footprints but also align with future industry trends toward circular economies.

Recent LCA research highlights the importance of device design in sustainability. High-value electronics, such as smartwatches, show environmental impacts dominated by integrated circuit production. Extending device lifetimes and designing for recycling can mitigate these effects. Conversely, low-value devices like TV remotes are more affected by substrate materials, encouraging the use of eco-friendly options like fiberglass (FR4). These findings guide SMT assembly toward greener practices, ensuring that future electronics are both functional and environmentally responsible.

Tip: Manufacturers can reduce waste by adopting clean production methods, such as low-temperature soldering and energy-efficient reflow ovens, to support sustainable SMT assembly.

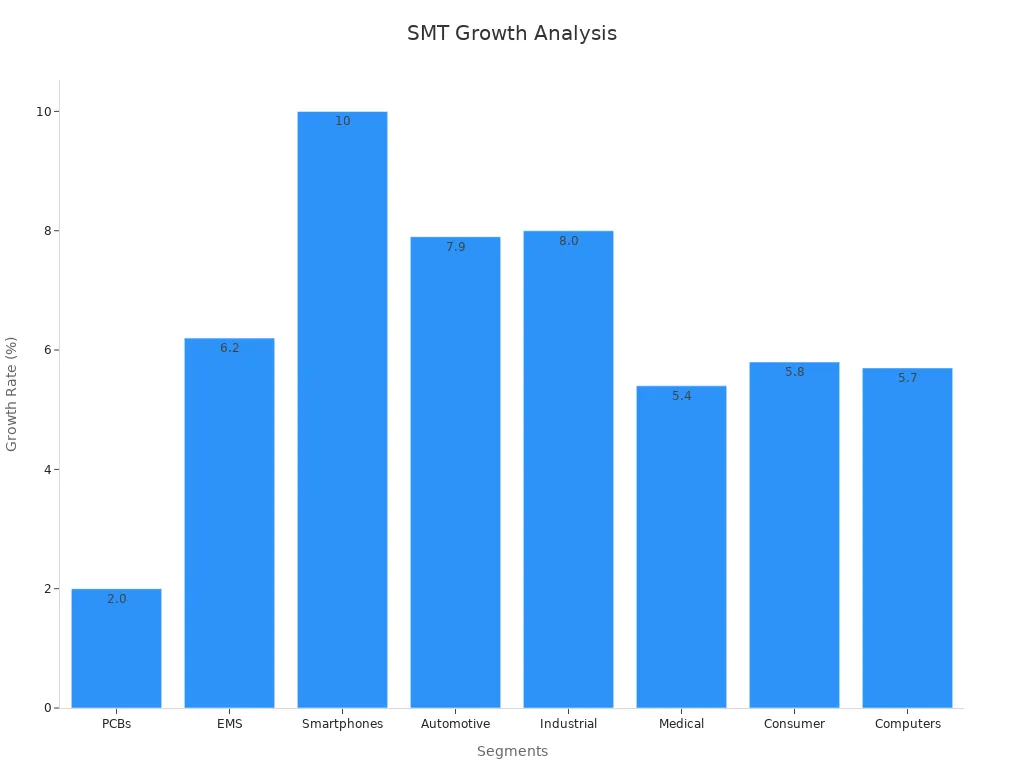

Surface mount technology remains vital in electronics manufacturing. The industry shows steady growth across multiple segments, as seen in the table below. Miniaturization, automation, and high-density designs drive innovation. SMT enables reliable, compact devices for sectors like consumer, automotive, and medical electronics. The chart highlights strong growth rates in these areas. Companies that adopt SMT principles and best practices will continue to lead in quality and efficiency.

| Segment | Market Size / Value (2015) | Growth Rate / CAGR (%) | Notes / Trends |

|---|---|---|---|

| Printed Circuit Boards (PCBs) | $56.4 billion (2015) | ~2.0% annually | Global market; China holds 47% share (~$26.2B) |

| Electronics Manufacturing Services (EMS) | $430 billion (2015) | 6.2% CAGR (2015-2020) | Contract manufacturing growth |

| Smartphones | 1.429 billion devices sold (2015) | 10% growth (2015), ~6.6% forecast | Largest electronics segment; key growth driver |

| Automotive Electronics | N/A | 7.9% annually (until 2018) | Above-average growth; HDI and microvia PCBs demand |

| Industrial Electronics | N/A | 8.0% annually | Growth driven by Industry 4.0 and M2M communication |

| Medical Electronics | $99 billion (2015) | 5.4% annually (until 2018) | Complex applications; steady growth |

| Consumer Electronics | N/A | 5.8% (starting 2017) | Recovery after decline; driven by 4K TVs, smart devices |

| Computers (Servers & Storage) | N/A | 5.7% annually (until 2018) | Growth due to IoT infrastructure and data centers |

SMT technology will continue to shape the future of electronics by supporting smarter, smaller, and more sustainable devices.

FAQ

What is the main advantage of SMT over through-hole technology?

Surface mount technology allows manufacturers to place smaller components directly onto circuit boards. This method increases production speed and enables compact device designs. SMT also reduces material costs and supports high-volume manufacturing.

Which industries use SMT the most?

Electronics, automotive, medical, industrial, and telecommunications industries rely heavily on SMT. These sectors benefit from the technology’s ability to produce reliable, miniaturized, and high-performance devices.

How does automation improve SMT assembly?

Automation increases placement accuracy and reduces human error. Machines handle repetitive tasks quickly, which boosts production efficiency. Automated inspection systems also help detect defects early, ensuring higher product quality.

What challenges do manufacturers face with SMT?

Manufacturers often encounter issues like solder paste defects, component misalignment, and thermal stress. They address these problems by using advanced inspection tools, strict quality control, and continuous staff training.

Tip: Regular equipment maintenance and process monitoring help reduce SMT assembly defects.

Written by Jack from AIChipLink.

AIChipLink, one of the fastest-growing global independent electronic components distributors in the world, offers millions of products from thousands of manufacturers, and many of our in-stock parts is available to ship same day.

We mainly source and distribute integrated circuit (IC) products of brands such as Broadcom, Microchip, Texas Instruments, Infineon, NXP, Analog Devices, Qualcomm, Intel, etc., which are widely used in communication & network, telecom, industrial control, new energy and automotive electronics.

Empowered by AI, Linked to the Future. Get started on AIChipLink.com and submit your RFQ online today!