An insulated gate bipolar transistor (IGBT) acts as a key switch in many power electronic systems. This device uses a unique structure that blends the fast switching and high input impedance of a MOSFET with the strong current handling of a BJT. The table below shows how an IGBT matches up with BJTs and MOSFETs in switching speed, conduction losses, and power handling.

| Performance Metric | BJT | IGBT | MOSFET |

|---|---|---|---|

| Switching Speed | Slow | Fast | Very Fast |

| Power Handling Capacity | Lower | Higher | Moderate |

| Input Impedance | Low | High | High |

IGBTs can control hundreds of kilowatts and operate at voltages above 1 kV. Their modules handle currents over 500 A and power densities above 500,000 W/cm². These features make IGBTs essential for high-power applications in modern industry.

Key Takeaways

-

IGBTs combine the easy voltage control of MOSFETs with the strong current handling of BJTs, making them ideal for high-power applications.

-

They switch quickly, handle high voltages and currents, and reduce energy loss, improving efficiency in systems like electric vehicles and renewable energy.

-

IGBTs are widely used in industries, transportation, renewable energy, and home appliances due to their reliability and power management capabilities.

-

Compared to MOSFETs and BJTs, IGBTs offer a balanced mix of high power capacity and simple control, fitting well in systems that need strong power but moderate switching speed.

-

Recent advancements in IGBT technology focus on improving efficiency, switching speed, thermal management, and reliability to meet growing market demands.

IGBT Fundamentals

Structure

An igbt has a simple but powerful design. It uses three terminals: the gate, collector, and emitter. These terminals help control the flow of electricity in high-power circuits. The structure of an igbt combines features from both MOSFETs and BJTs. Inside, the device has an NPNP layer arrangement. This means it has layers of different materials stacked together: N-type, P-type, N-type, and P-type. Each layer plays a role in how the device handles current and voltage.

The gate terminal sits on top of an insulating layer. This layer separates the gate from the rest of the device. The collector and emitter connect to the outer layers. This setup allows the igbt to handle large amounts of power while staying easy to control.

Note: The NPNP structure helps the igbt manage both high voltage and high current. This makes it a good choice for many power applications.

Operation

The operation of an igbt centers on its gate. The gate works like a switch. When a voltage appears at the gate, it turns the device on. When the voltage is removed, the device turns off. This voltage-driven control is different from a BJT, which needs a current to turn on. The igbt only needs a small voltage at the gate, so it uses less energy to switch on and off.

The table below shows measured data that highlights the voltage-driven nature and performance of the igbt:

| Parameter | Description / Data |

|---|---|

| Equivalent Circuit | IGBT can be turned on/off by voltage signal, enabling logic-level driving |

| Saturation Characteristic | For 600 V, 100 A IGBT |

| Safe Operating Area | For 600 V, 100 A IGBT |

| Switching Time Control | Gate resistor value controls switching time; lower resistor reduces switching time |

| Gate-to-Emitter Junction | Behaves as capacitance affecting switching speed |

| Voltage Ratings | Up to 1200 V |

| Current Ratings | Up to 400 A |

| Switching Speeds | From <1 microsecond to 10 microseconds |

| Operating Frequency | Up to 20 kHz |

This data shows that the igbt can handle high voltage and current. It also shows that the device responds quickly to changes at the gate. The gate-to-emitter junction acts like a capacitor. This means the speed of switching depends on how fast the voltage at the gate changes.

The igbt stands out because it blends the best parts of MOSFETs and BJTs. The gate uses MOSFET technology, so it has high input impedance and fast response. The main current path uses BJT technology, so it can handle large amounts of power. This combination gives the igbt strong switching capabilities and low power loss.

The table below compares how igbt, MOSFET, and BJT devices control current and manage switching:

| Device Type | Current Flow Control | Carrier Type | Control Method | Impact on Switching and On-State Voltage |

|---|---|---|---|---|

| IGBT | Dual carrier conduction (electrons and holes) | Bipolar (electrons + holes) | Voltage-controlled (gate-emitter voltage) | Lower on-state voltage due to conductivity modulation by hole injection; slower turn-off due to tail current from holes; presence of punch-through (PT) and non punch-through (NPT) types affects switching speed |

| Power MOSFET | Majority carrier conduction (electrons only) | Unipolar (electrons) | Voltage-controlled (gate voltage) | Higher on-state voltage compared to IGBT; faster switching speed due to absence of minority carrier tail current |

| BJT | Current-controlled (base current controls collector current) | Bipolar (electrons and holes) | Current-controlled (base current) | Faster switching but higher power consumption; susceptible to latchup unlike MOSFET and IGBT |

The igbt uses both electrons and holes to carry current. This dual carrier flow helps reduce the voltage drop when the device is on. It also means the igbt can handle more power than a MOSFET. However, the presence of holes can slow down the turn-off process, which affects the switching speed.

The insulated gate bipolar transistor offers a unique mix of features. It provides high power handling, fast switching, and easy voltage control. These qualities make the igbt a popular choice in many modern power systems. Engineers often select igbt devices for their strong switching capabilities and ability to manage large amounts of power with low losses.

Insulated Gate Bipolar Transistor Applications

Insulated gate bipolar transistors, or IGBTs, play a vital role in many modern applications. Their ability to handle high power, high voltage, and high current makes them essential in power electronic systems. Engineers use IGBTs in a wide range of fields, from heavy industry to home appliances. The following sections explore the main applications of IGBTs and show how these devices improve performance and reliability.

Industrial Uses

Factories and industrial plants rely on IGBTs for high-power and high-voltage applications. These devices control large amounts of electricity in motor drives, inverters, and power grids. IGBTs help manage high current and high voltage, making them ideal for running heavy machinery and automation systems.

-

IGBTs support parallel module operation, which improves current sharing and system reliability.

-

Advanced gate drivers provide isolated temperature measurement, allowing precise thermal management.

-

Active clamping protects against overvoltage, increasing device durability.

-

IGBTs meet strict standards for electromagnetic interference and mechanical strength.

-

Rigorous testing ensures reliability under industrial conditions, including thermal cycling and voltage stress.

-

Compact designs allow engineers to connect multiple modules in parallel, boosting current capacity and saving space.

-

Trench-gate and silicon carbide IGBTs increase efficiency and reduce switching losses.

-

Factory automation and robotics use IGBT modules for their high thermal stability and efficient switching.

-

Companies like Hitachi Energy and onsemi develop advanced IGBT modules to reduce energy use in heating and cooling systems.

IGBTs also power high-voltage power supplies and renewable energy converters in industrial settings. Their strong performance and reliability make them a top choice for demanding power electronic systems.

Renewable Energy

Renewable energy systems depend on IGBTs for efficient power conversion. Solar inverters and wind turbines use IGBTs to convert and control electricity from renewable sources. These devices handle high voltage and high current, ensuring stable operation even when energy production changes.

IGBTs in solar inverters help manage the flow of electricity from solar panels to the grid. They switch quickly and handle high power, which improves the efficiency of renewable energy converters. Wind turbines also use IGBTs to control the speed and output of their generators. This flexibility supports reliable and efficient energy production.

The growing use of IGBTs in renewable energy applications shows their value in building a cleaner and more reliable power grid.

Transportation

IGBTs have transformed transportation by enabling efficient and reliable electric vehicle (EV) and train systems. In EVs, IGBT modules control the motor and manage battery power. These modules handle high current and high voltage, which is critical for fast acceleration and long driving range.

High-power IGBT modules in EVs and hybrids support modular design, allowing engineers to customize systems for specific needs. These modules outperform older devices by providing higher power handling and faster switching speeds. They operate reliably under tough conditions, such as high temperatures, vibration, and humidity.

A case study on EV inverters shows that IGBT modules reduce power loss and manage junction temperature. Temperature stress causes about 55% of failures in power electronic components. By controlling junction temperature, IGBTs improve the reliability and efficiency of EV drive systems. This approach supports better performance and longer system life.

Trains and high-speed rail systems also use IGBTs in traction inverters. These devices enable energy-efficient power conversion and reduce energy losses. Advances in IGBT technology, such as trench-gate and silicon carbide designs, further improve efficiency and durability in transportation applications.

Home Appliances

IGBTs have become common in home appliances that require efficient motor drives and power control. Devices like air conditioners, washing machines, and refrigerators use IGBTs to manage high voltage and high current. These applications benefit from the fast switching and low power loss of IGBTs.

Manufacturers have introduced IGBTs with improved switching loss characteristics for home appliances. For example, Toshiba launched a 650 V IGBT for air conditioners, while Renesas offers IGBTs with up to 1200 V and 300 A ratings. These improvements boost power efficiency and reliability in consumer devices.

The table below shows typical voltage and current ranges for IGBTs in home appliance applications:

| Voltage Range (V) | Current Range (A) | Application Context |

|---|---|---|

| 300 - 400 | 10 - 30 | Coil drivers, home appliances |

| 600 - 750 | Up to 320 | High-frequency applications |

| ≥ 1200 | 3 - 75 | Discrete packages for appliances |

| Up to 1700 (bare die) | Up to 200 | Motor control, home appliances |

Technical studies show that the reliability of IGBTs in consumer devices depends on the quality of solder joints. Voids in solder joints can reduce fatigue life by nearly 60%. Careful design and testing help ensure that IGBTs in home appliances last longer and perform better.

IGBTs continue to expand their role in home appliances as the global market grows. Their ability to handle high power, high voltage, and high current makes them a key part of modern consumer electronics.

IGBT vs. Other Devices

MOSFETs

Engineers often compare the igbt with the power MOSFET. Both devices use a voltage at the gate to control current. The igbt can handle higher current and higher voltage than a MOSFET. However, MOSFETs switch faster. Empirical studies show that MOSFETs have the highest switching speeds. They work well as parallel switches in circuits that need quick changes. The igbt, on the other hand, offers a simple gate drive and low switching energy because of its high gate impedance. Still, its switching speed is lower than that of a MOSFET. Behavioral models and real-world tests confirm that MOSFETs outperform the igbt in switching speed. Engineers choose MOSFETs for high-frequency tasks, while the igbt fits better in high-power and high voltage systems.

BJTs

The igbt also shares features with the bipolar junction transistor (BJT). Both can handle large currents. The igbt, though, uses a voltage to control the gate, while the BJT needs a current at the base. This difference means the igbt has a higher input impedance and uses less energy to switch. The BJT switches slower and needs more complex drive circuits. The igbt combines the easy control of a MOSFET with the strong current handling of a BJT. This blend makes the igbt a popular choice for many power electronics applications.

Selection Factors

Selecting the right device depends on the needs of the application. The table below shows key differences:

| Characteristic | IGBT | Power MOSFET | Power Bipolar Transistor |

|---|---|---|---|

| Current Rating | High | Low | High |

| Voltage Rating | Very High | High | High |

| Switching Speed | Medium | Fast | Slow |

| Input Impedance | High | High | Low |

| Output Impedance | Low | Medium | Low |

The igbt stands out for its ability to handle very high voltages and currents with a simple gate drive. It works best in systems that need strong power management but do not require the fastest switching. Engineers also look at device types. Punch-Through (PT) igbt devices switch faster but work best below 600V. Non-Punch-Through (NPT) igbt devices handle higher voltages and offer better thermal stability. The igbt is unidirectional, so extra circuits are needed for AC systems. Cost, reliability, and thermal needs also guide the choice. The igbt remains a top pick for high voltage and high current uses, especially where switching speed is not the main concern.

IGBT Advancements

Efficiency

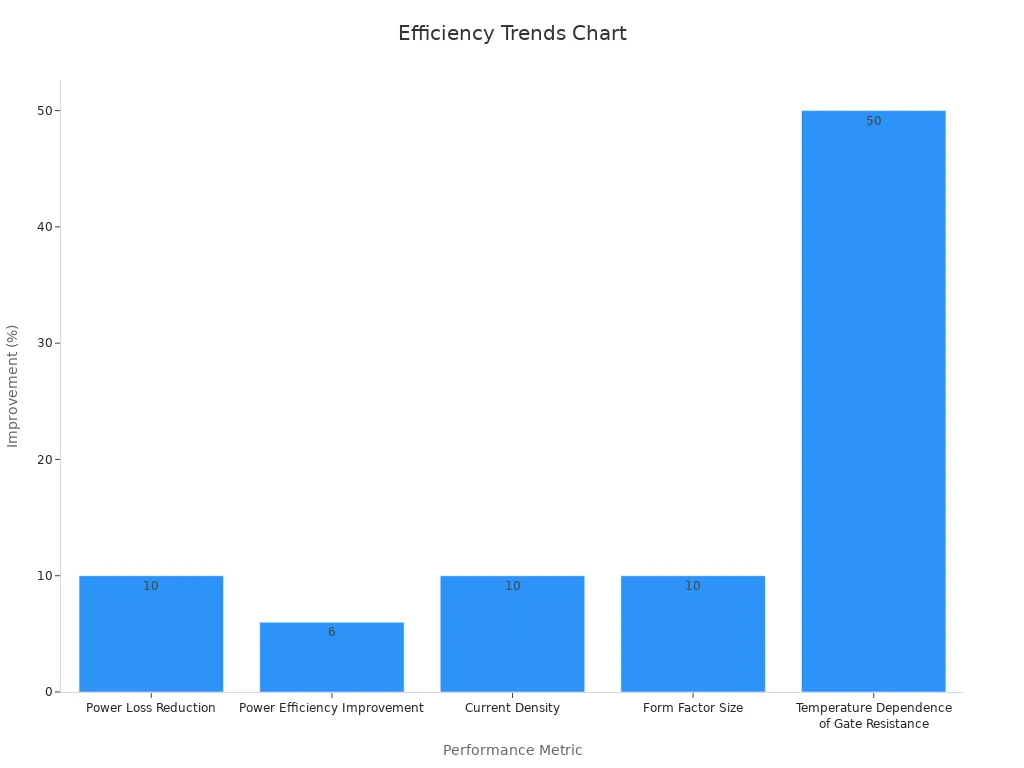

Modern igbt technology shows clear improvements in efficiency. Engineers have optimized device structures to reduce conduction losses and improve current density. New-generation igbt modules, such as the AE5 series, achieve up to 6% higher efficiency at the same current density compared to older models. These modules also show a 10% reduction in power losses and a smaller form factor. Numerical studies confirm that advanced cooling strategies, like optimized water-cooled plates, further boost efficiency by keeping junction temperatures low and uniform. The 2025 review on igbt thermal management highlights the importance of temperature control, thermal resistance, and reliability for efficient operation.

| Performance Metric | New-Generation IGBTs (AE5 Series) | Older Models |

|---|---|---|

| Power Loss Reduction | 10% lower power losses | Baseline |

| Power Efficiency Improvement | Up to 6% higher efficiency | Baseline |

| Current Density | 10% higher current density | Baseline |

| Form Factor Size | 10% smaller | Baseline |

| Saturation Voltage | 1.3 V (new standard) | Higher |

| Threshold Voltage Variation | ±0.5 V (50% improvement) | Larger variation |

| Temperature Dependence of Gate Resistance | Reduced by 50% | Higher |

| Short-Circuit Withstand Time | 4 µs at 400 V | Lower robustness |

| Operating Junction Temperature Range | −40 to 175°C stable performance | Less stable |

Switching Speed

Switching speed has improved greatly in modern igbt designs. Early igbt devices switched slowly and faced issues like latchup. Today, fifth-generation igbt modules reach switching speeds close to those of MOSFETs. Field Stop technology and enhanced lifetime control techniques reduce tail current, allowing faster turn-off. Engineers have also improved gate drive requirements and temperature stability, which ensures consistent switching characteristics. New trench-gate igbt designs and hybrid power switches with silicon-carbide MOSFETs further enhance switching capabilities and reduce losses. These advancements help igbt modules perform well in high power and high current applications.

-

Field Stop technology absorbs excess carriers for faster switching.

-

Non-punch-through designs improve thermal stability and reliability.

-

Integrated diodes and protective circuits boost system performance.

Thermal Management

Thermal management is critical for igbt modules, especially in high power systems. Air cooling with heat sinks works for low-power devices, but high-power igbt modules need advanced solutions. Liquid cooling methods, such as cold plates and vapor cooling loops, provide much higher heat transfer rates. These techniques keep junction temperatures low and reduce temperature gradients across the module. Numerical studies show that liquid cooling maintains safe junction temperatures even at power dissipation rates above 1200 W. Cold plates transfer heat directly from the igbt to a coolant, which then moves heat away efficiently. This approach supports compact designs and reliable operation at high current and high voltage.

Tip: Liquid cooling offers the lowest thermal resistance and the largest safety margin for igbt modules in demanding applications.

Reliability

Reliability remains a top priority for igbt development. Modern igbt modules use new materials and advanced packaging to withstand harsh conditions. Long-term studies show that improved gate driver technologies can monitor device health in real time. These systems detect abnormal operations and aging, which helps prevent random failures and predict wear-out. Engineers address failure mechanisms at every level, from the semiconductor die to the system. Redundant converter designs and condition monitoring extend device lifetime. International research teams continue to develop solutions that make igbt modules more robust and durable, especially in high power and high current environments.

The insulated gate bipolar transistor stands out for its unique structure, efficient operation, and wide range of applications. Engineers value igbt technology for its strong power handling, reliable switching, and adaptability. Recent advancements include trench gate designs, 3D packaging, and the use of silicon carbide and gallium nitride.

-

Key uses: electric vehicles, renewable energy, industrial automation, and smart electronics.

-

Ongoing trends: rapid market growth, new wafer processes, and intelligent modules.

| Year | Global Market Size (USD Million) | CAGR |

|---|---|---|

| 2024 | 5,750 | 9.2% |

| 2032 | 11,626.49 |

Staying informed about igbt innovation helps engineers choose the best solutions for modern power systems.

FAQ

What makes an IGBT different from a MOSFET?

IGBTs handle higher voltages and currents than MOSFETs. They combine the easy control of MOSFETs with the strong power handling of BJTs. Engineers choose IGBTs for high-power systems, while MOSFETs work best in fast-switching, lower-power circuits.

Where do engineers use IGBTs most often?

Engineers use IGBTs in electric vehicles, industrial motor drives, renewable energy systems, and home appliances. These devices help control large amounts of electricity safely and efficiently.

How do IGBTs improve energy efficiency?

IGBTs reduce power loss during switching and conduction. Modern designs use advanced materials and cooling methods. These improvements help systems save energy and lower heat output.

Can IGBTs fail, and how do engineers prevent this?

| Failure Cause | Prevention Method |

|---|---|

| Overheating | Use better cooling |

| Overvoltage | Add protective circuits |

| Aging | Monitor device health |

Engineers use these methods to keep IGBTs reliable and safe.