A proximity sensor is a non-contact sensor that detects the presence or absence of nearby objects without touching them. This sensor uses signals such as electromagnetic fields, ultrasonic waves, or light beams to sense changes in its environment. High-speed performance and durability make proximity sensors vital in many industries. The global market for these sensors reached USD 4.5 billion in 2023, with projections showing continued growth.

Key Takeaways

-

Proximity sensors detect nearby objects without touching them, using signals like electromagnetic fields, light, or sound.

-

Different types of proximity sensors work best for specific materials and environments, such as inductive for metals and photoelectric for almost any object.

-

Key features like sensing range, response time, and environmental resistance affect sensor performance and suitability for various applications.

-

Proximity sensors improve safety and efficiency in industries like manufacturing, automotive, consumer electronics, and security systems.

-

Proper installation, regular cleaning, and correct alignment help prevent false triggers and extend the sensor’s lifespan.

Proximity Sensor Basics

What Is a Proximity Sensor

A proximity sensor is a device that detects the presence of objects within a certain range without making physical contact. This technology enables non-contact object detection, which helps prevent wear and tear on both the sensor and the object. Proximity sensors play a key role in many modern systems, from industrial machines to consumer electronics.

Researchers have validated the accuracy of proximity sensors through real-world experiments. For example, scientists used proximity loggers on animal collars to monitor interactions among cattle. The sensors recorded proximity events and matched them with expected animal behavior, confirming that the devices can accurately detect nearby objects within a set distance. In another study, wearable sensors measured social proximity among children with autism spectrum disorders. The results matched video observations, showing that the sensors can reliably detect interpersonal distances in educational settings. These studies demonstrate that a proximity sensor can detect nearby objects and events with high accuracy in practical scenarios.

Note: Proximity sensors do not require direct contact to function, making them ideal for applications where hygiene, safety, or durability is important.

How It Works

A proximity sensor operates by sensing changes in its environment, such as electromagnetic fields, light, or capacitance. The sensor detects the presence of an object when it enters its sensing range. Most proximity sensors use a combination of hardware and software to achieve reliable detection.

-

Proximity sensors often use Received Signal Strength Indicator (RSSI) to estimate the distance between devices.

-

The sensor system includes several modules:

-

A processing module, such as an ESP32 microcontroller with Bluetooth Low Energy (BLE) and Wi-Fi.

-

An energy module, usually a LiPo battery with power management.

-

A GPS module for location tracking.

-

An Inertial Measurement Unit (IMU) for motion data.

-

-

The sensor communicates with other devices using BLE in beacon mode. It scans every few seconds to detect nearby objects and collects data like RSSI values and device identifiers.

-

Experimental tests show that the signal strength decreases as the distance increases, following models like the Friis equation. This relationship allows the sensor to estimate how close an object is.

The following table shows typical technical features of a proximity sensor:

| Feature | Description |

|---|---|

| Operating Voltage | Typically ranges from 3.3V to 5V |

| Sensing Distance | Varies by model, typically from 2mm up to 10cm |

| Output Type | Digital (High/Low) or Analog (voltage proportional to distance) |

| Pin Configuration | VCC (Power supply), GND (Ground), OUT (Output signal), Optional pins for control functions |

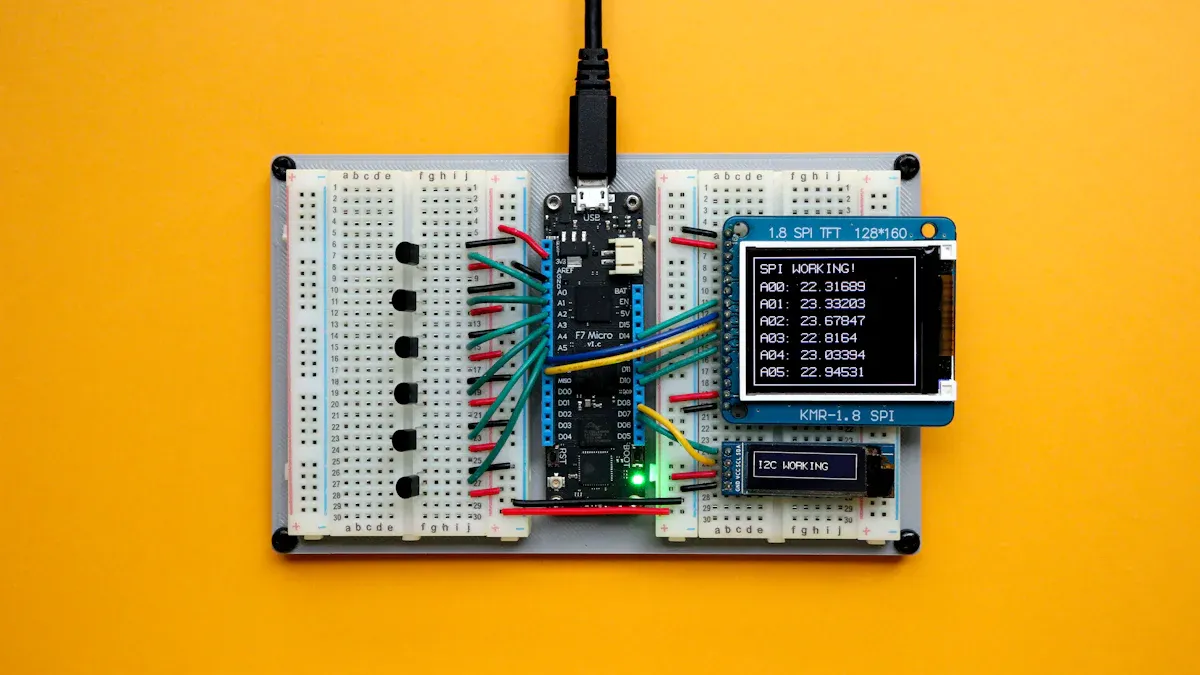

A practical example involves connecting a proximity sensor to a microcontroller, such as an Arduino. The sensor receives power, sends its output to the microcontroller, and triggers actions like turning on an LED when it detects the presence of an object.

const int sensorPin = 2; // Sensor output pin

const int ledPin = 13; // LED pin

void setup() {

pinMode(sensorPin, INPUT);

pinMode(ledPin, OUTPUT);

}

void loop() {

int sensorValue = digitalRead(sensorPin);

if (sensorValue == HIGH) {

digitalWrite(ledPin, HIGH); // Object detected

} else {

digitalWrite(ledPin, LOW); // No object

}

}

Some proximity sensors, such as capacitive types, use circuits that measure changes in capacitance when an object approaches. The sensor firmware filters out noise and tracks slow environmental changes, ensuring accurate detection. Engineers can tune the sensor by adjusting hardware and software settings to optimize the sensing range and reduce false triggers.

Tip: Proximity sensors offer fast response times and stable sensing ranges, making them reliable for many applications, including activating lights, stopping machinery, and enabling keyless entry systems.

Proximity Sensor Types

Proximity sensors come in several main types, each with a unique way of detecting objects. The classification of these sensors depends on their operating principles and the materials they can sense. Below is a summary table that compares key characteristics:

| Sensor Type | Operating Principle | Detects | Sensing Range | Environmental Sensitivity |

|---|---|---|---|---|

| Inductive | Electromagnetic induction | Metal objects | Up to ~60 mm | Robust in harsh environments |

| Capacitive | Change in capacitance | Metals, powders, solids | 3 to 60 mm | Sensitive to non-target materials |

| Passive Infrared (PIR) | Detects infrared radiation | Warm bodies (humans, animals) | Up to 10 meters | Sensitive to temperature changes |

| Photoelectric | Light emission and detection | Almost any object | Up to several meters | Affected by dust, light, color |

| Magnetic | Magnetic field detection | Magnetic materials | Variable (up to 2 m) | Sensitive to magnetic interference |

Inductive Proximity Sensor

Inductive proximity sensors use electromagnetic induction to detect metal objects. When a metal target enters the sensor’s electromagnetic field, eddy currents form in the metal, causing a change in the sensor’s output. Experimental setups use standardized metal plates to measure switching distances, confirming the sensor’s ability to respond to different metals. These sensors work well in harsh environments and provide reliable detection for industrial automation.

Inductive sensors are ideal for applications where only metal objects need to be detected, such as position sensing in machinery.

Capacitive Proximity Sensor

Capacitive proximity sensors operate by measuring changes in capacitance between their electrodes and nearby objects. They can sense both metallic and non-metallic materials, including powders and solids. Researchers validate these sensors by calibrating them against precise measurement systems and using simulations to analyze electric fields. Regular recalibration ensures accuracy over time. Capacitive sensors are useful in applications where detection of a wide range of materials is required.

Passive Infrared Sensor

Passive infrared (PIR) sensors detect infrared radiation emitted by warm objects, such as people or animals. The sensor measures changes in heat patterns within its field of view. Studies show that PIR sensors can predict movement direction with 100% accuracy and count people with up to 89% accuracy. These sensors are common in security systems and automatic lighting.

-

PIR sensors do not emit energy; they only sense changes in infrared radiation.

-

They work best for detecting motion in open spaces.

Photoelectric Sensor

Photoelectric sensors use a beam of light to detect objects. When an object interrupts or reflects the light, the sensor triggers a response. Technical reports show that these sensors can identify colors, contrast, and even invisible markings. Modern photoelectric sensors use advanced calibration and anti-interference features to improve accuracy in challenging environments.

-

Types include through-beam, retro-reflective, and diffuse-reflective sensors.

-

They can detect almost any object, regardless of material.

Magnetic Sensor

Magnetic sensors detect the presence of magnetic fields, usually from magnets or magnetic materials. Experiments with wearable magnetic field sensors show accurate detection within a 2-meter range, with errors less than 10 centimeters. These sensors are robust against environmental factors that affect other sensor types and are often used in access control and position sensing.

Magnetic sensors are especially useful in applications where high accuracy and resistance to interference are important.

Key Features

Sensing Range

Sensing range describes how far a proximity sensor can detect an object. Different sensor types offer different ranges and accuracy levels. Several factors influence this feature:

-

Photoelectric sensors use modulated light beams. Through-beam types provide the longest range and highest accuracy, while retro-reflective and diffuse-reflective types offer moderate and shorter ranges.

-

Ultrasonic sensors emit sound waves and measure the time it takes for the echo to return. Through-beam ultrasonic sensors detect interruptions, and reflective types sense bounced signals.

-

Capacitive sensors detect changes in electric fields. They work well with non-metallic objects and can have long ranges, but temperature and humidity may affect their performance.

-

Magnetic sensors sense magnetic fields and can reach long distances. However, electromagnetic interference and temperature changes can impact their accuracy.

-

Environmental conditions, such as humidity, temperature, and electromagnetic noise, play a critical role in determining the effective sensing range.

Resolution and refresh rate also matter. For example, infrared sensors can detect changes as small as 5 mm, while laser sensors can reach 1 mm or better. LiDAR sensors can measure up to 2000 meters with high accuracy.

Response Time

Response time measures how quickly a proximity sensor reacts to the presence of an object. Standardized tests use precise timing methods to ensure accuracy. For instance, infrared proximity sensors often measure the time between a visual cue, like an LED turning on, and the moment a person interrupts the sensor beam. These tests use intervals as short as 1 millisecond. Multiple trials help average out any errors, and sensors connect to mobile apps for real-time data recording. Improved testing methods, such as integrating microheaters in MEMS thermopile sensors, have reduced response times from 12.7 ms to 6.9 ms, showing the importance of precise measurement techniques.

Environmental Resistance

Proximity sensors often operate in harsh environments. Manufacturers design them to withstand water, dust, chemicals, and extreme temperatures. Some key features include:

-

Waterproof models that function even when submerged or exposed to high-pressure washdowns.

-

Sealed housings that prevent fogging, corrosion, and dust ingress.

-

Resistance to chemicals, depending on the housing material.

-

Robust construction using stainless steel or high-grade plastics.

-

Potting or encapsulation of electronics to block moisture and vibration.

-

IP ratings (such as IP65, IP67, IP68, IP69K) that define protection against dust, water jets, immersion, and washdowns.

Tests show that sensors can survive fluid immersion, high humidity, UV exposure, salt fog, and vibration cycles without losing performance. These features ensure reliable operation in industries like food processing, pharmaceuticals, and aerospace.

Output Options

Proximity sensors offer various output options to suit different applications. Common types include digital (on/off), analog (variable voltage), and communication protocols like Bluetooth. Studies comparing internal and external infrared emitter-detector (IRED) sensors found strong correlation coefficients (above 0.97) between sensor pairs, even in challenging conditions like fog. Linear regression slopes ranged from 0.97 to 1.05, showing consistent performance. In industrial and clinical settings, advanced output configurations improve accuracy and reliability. For example, machine learning models applied to sensor outputs can enhance prediction and classification tasks, while robust output signals help monitor processes and detect faults.

Tip: Choosing the right output option depends on the application’s needs for speed, accuracy, and data integration.

Applications

Industrial Automation

Factories and production lines rely on sensors to improve efficiency and safety. Workers use inductive sensors to detect metal parts on conveyor belts. Capacitive sensors help monitor both solid and liquid materials. Photoelectric sensors use light to count products or check for missing items. Ultrasonic sensors measure distances in harsh environments.

-

Detection range and object material compatibility play a key role in choosing the right sensor.

-

Environmental factors like temperature, humidity, and dust affect performance.

-

Output types such as NPN, PNP, or analog signals connect to control systems.

-

Power supply requirements ensure stable operation.

-

Integration with IoT and AI allows real-time monitoring and predictive maintenance.

Manufacturers report increased productivity, better product quality, and reduced costs after installing these sensors. Real-time monitoring helps detect problems early, which improves worker safety and reduces downtime.

Automotive Uses

Modern vehicles use sensors to monitor engine temperature, control airbags, and support advanced driver-assistance systems. Temperature sensors help prevent engine failure and improve fuel efficiency. Pressure sensors in tire monitoring systems alert drivers to unsafe conditions.

Automotive factories use proximity sensors to automate assembly lines and ensure precise placement of parts. These sensors also support collision avoidance and parking assistance features, making driving safer and more convenient.

Consumer Devices

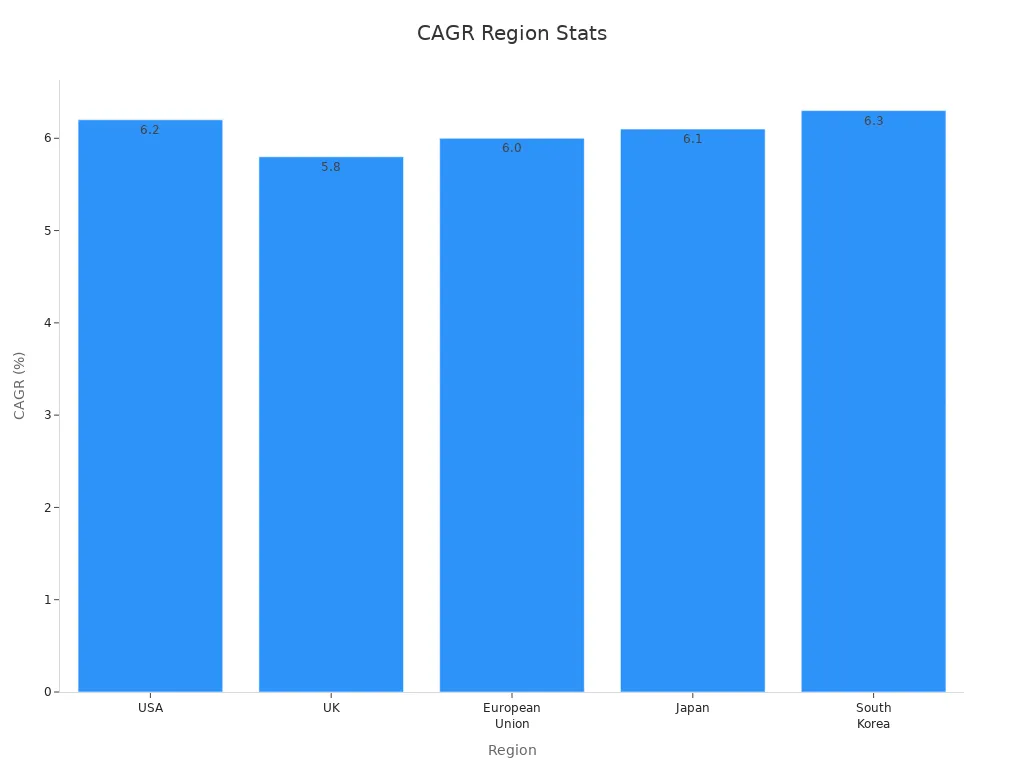

Proximity sensors appear in smartphones, tablets, and wearable devices. They turn off screens during calls and enable touchless controls. The following table shows how different regions drive growth in consumer device markets:

| Region | Key Market Drivers in Consumer Devices and Related Sectors | CAGR (2025-2035) |

|---|---|---|

| USA | Growth in factories, car safety systems, IoT gadgets, robotics, self-driving systems | 6.2% |

| UK | Increasing factory automation, smart homes, wearables, touchless sensors, radar in transport | 5.8% |

| European Union | Strict regulations, automotive safety sensors, touch-free tech in public spaces, smart robots | 6.0% |

| Japan | Robotics, factory automation, smart city projects, healthcare touchless monitoring | 6.1% |

| South Korea | Consumer electronics, automated cars, factory safety, 5G devices, radar sensors for self-driving cars | 6.3% |

Asia-Pacific countries lead in adopting proximity sensors for electric vehicles, smart cities, and IoT devices. Western markets focus on factory automation and touchless technology in consumer gadgets.

Security Systems

Security systems use proximity sensors to detect people near restricted areas or hazardous machines. These sensors trigger alarms, automatic shutdowns, or emergency responses. Photoelectric detectors alert staff to unauthorized access, while thermal scanners activate fire sprinklers.

Keyless entry systems use proximity sensors to allow secure access without physical keys. These sensors also help prevent equipment damage by measuring distances and avoiding collisions. Integration with AI and IoT improves real-time response and supports automated security management.

Proximity sensors make security systems more reliable and convenient by enabling non-contact detection and fast response to threats.

Installation and Maintenance

Setup Tips

Proper installation ensures reliable performance from any proximity sensor. Installers should always follow the manufacturer’s guidelines for mounting height, angle, and distance. They must avoid placing sensors near strong electromagnetic sources, such as motors or radio transmitters, to reduce interference. Using shielded cables and grounding the system helps prevent signal noise. Installers should check alignment carefully, especially for photoelectric and ultrasonic types, as incorrect positioning often leads to missed detections.

Tip: Test the sensor after installation by moving a target object through its sensing range to confirm accurate detection.

Maintenance

Routine maintenance keeps sensors operating efficiently and extends their lifespan. Cleaning the sensor face with a soft cloth removes dust and debris that can block detection. Technicians should inspect wiring and connectors for signs of wear or corrosion. Maintenance schedules vary by agency and environment. The table below summarizes observed maintenance and failure rates:

| Factor | Range/Observation |

|---|---|

| Maintenance response time | 0.5 hours to several days |

| Annual failure rate | <1% to over 10% |

| Proximity to maintenance site | Varies significantly |

| Failure pattern | Earlier failure after repeated repairs |

Reliability handbooks and databases provide further guidance on expected failure rates and maintenance intervals. Devices that undergo multiple repairs may fail sooner, so tracking maintenance history helps optimize schedules.

Troubleshooting

Common issues can disrupt sensor operation. Technicians often encounter:

-

False triggering from electrical interference or vibration

-

Complete sensor failure despite power supply

-

Incorrect voltage levels, checked with a multimeter

-

Misalignment or improper positioning

-

Output signal problems, diagnosed by measuring voltage or current

-

Environmental interference, such as EMI or humidity

-

Need for firmware updates or recalibration

-

Persistent noise, reduced by installing conductive shielding

FAQs often address false triggering, calibration frequency, and environmental protection. Following industry standards and using advanced diagnostics improves reliability.

Proximity sensors play a vital role in modern automation and safety. They offer accurate, non-contact detection for many industries. Each sensor type—capacitive, inductive, photoelectric, ultrasonic, and magnetic—serves unique needs.

-

Capacitive sensors work well for non-conductive materials but may react to humidity.

-

Integration with other sensors can reduce interference.

-

Key factors include detection range, durability, and response time.

Selecting the right sensor depends on the environment and target material. Regular maintenance ensures stable performance and long-term reliability.

FAQ

What objects can proximity sensors detect?

Proximity sensors can detect metals, plastics, liquids, powders, and even people. The type of sensor determines what it can sense. For example, inductive sensors detect metals, while capacitive sensors can sense both solids and liquids.

How do users prevent false triggers in proximity sensors?

Users can reduce false triggers by installing sensors away from strong electromagnetic sources. Proper alignment and regular cleaning also help. Shielded cables and correct grounding improve reliability.

Can proximity sensors work outdoors?

Many proximity sensors work outdoors. Models with high IP ratings resist water, dust, and temperature changes. Manufacturers design these sensors for harsh environments, including rain and sunlight.

What is the typical lifespan of a proximity sensor?

| Sensor Type | Average Lifespan |

|---|---|

| Inductive | 5-10 years |

| Capacitive | 3-8 years |

| Photoelectric | 2-7 years |

| Magnetic | 5-10 years |

Proper maintenance extends sensor life and ensures stable performance.

Written by Jack Elliott from AIChipLink.

AIChipLink, one of the fastest-growing global independent electronic components distributors in the world, offers millions of products from thousands of manufacturers, and many of our in-stock parts is available to ship same day.

We mainly source and distribute integrated circuit (IC) products of brands such as Broadcom, Microchip, Texas Instruments, Infineon, NXP, Analog Devices, Qualcomm, Intel, etc., which are widely used in communication & network, telecom, industrial control, new energy and automotive electronics.

Empowered by AI, Linked to the Future. Get started on AIChipLink.com and submit your RFQ online today!

.png&w=256&q=75)