Understanding the difference between system on chip and system on module can change how a new device turns out. Think about a team making a smart gadget. They need to pick if a system on chip gives enough integration for what they want, or if a system on module gives better integration and helps them build faster. Picking the right one changes how fast the product gets to stores and how well it works. Readers should think about what their own projects need as they learn.

Key Takeaways

-

SoC puts many computer parts on one chip. This makes devices smaller and uses less power. It is good for products that need to be fast and save energy.

-

SoM has a SoC and extra hardware on a small board. It gives more choices and helps teams build things faster. Upgrades are easy with SoM.

-

SoC is best for making lots of the same product. It costs less for each unit. SoM is better for projects that need quick design and easy changes. It also lowers risk.

-

SoC is great for fast and efficient devices like smartphones. SoM is good for flexible and reliable systems in fields like medical and automotive.

-

Teams should choose SoC or SoM based on what the project needs. They should also think about budget and future plans. SoM is good for fast results and upgrades. SoC is better for making many fixed designs.

Key Differences

SoC vs. SoM

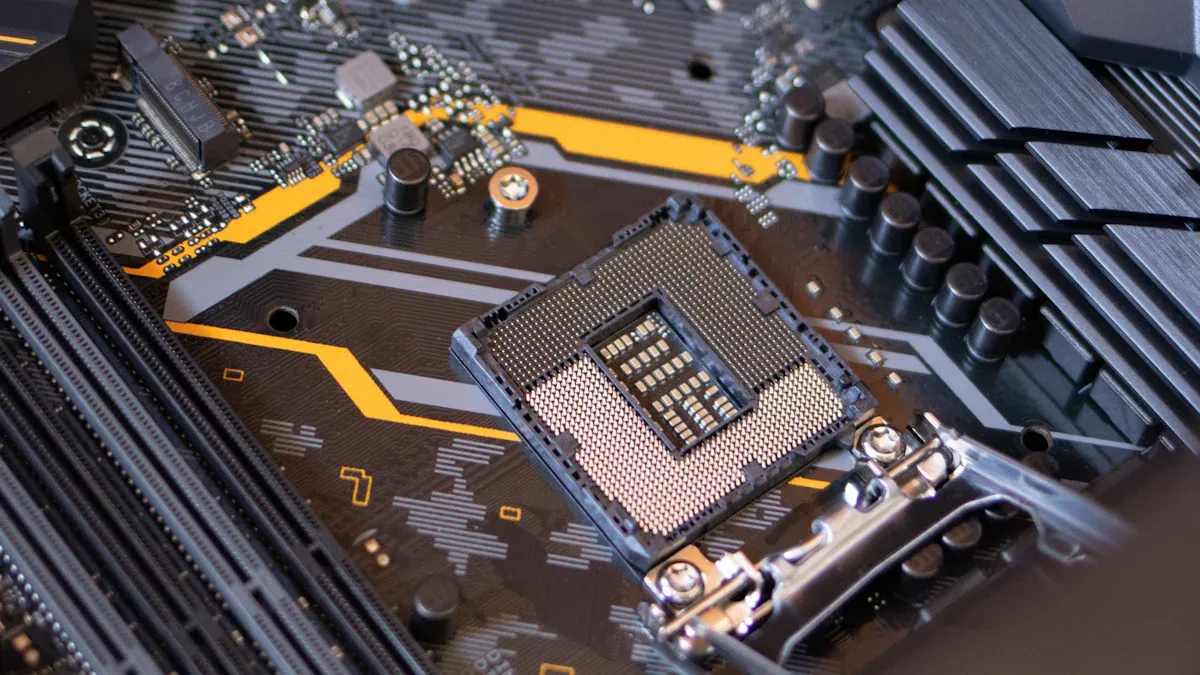

A system on chip puts many computer parts on one chip. This chip usually has the processor, memory, and controls for input and output. SoC designs help make devices smaller and use less energy. Many smartphones and tablets use SoC because they need to save space and battery power.

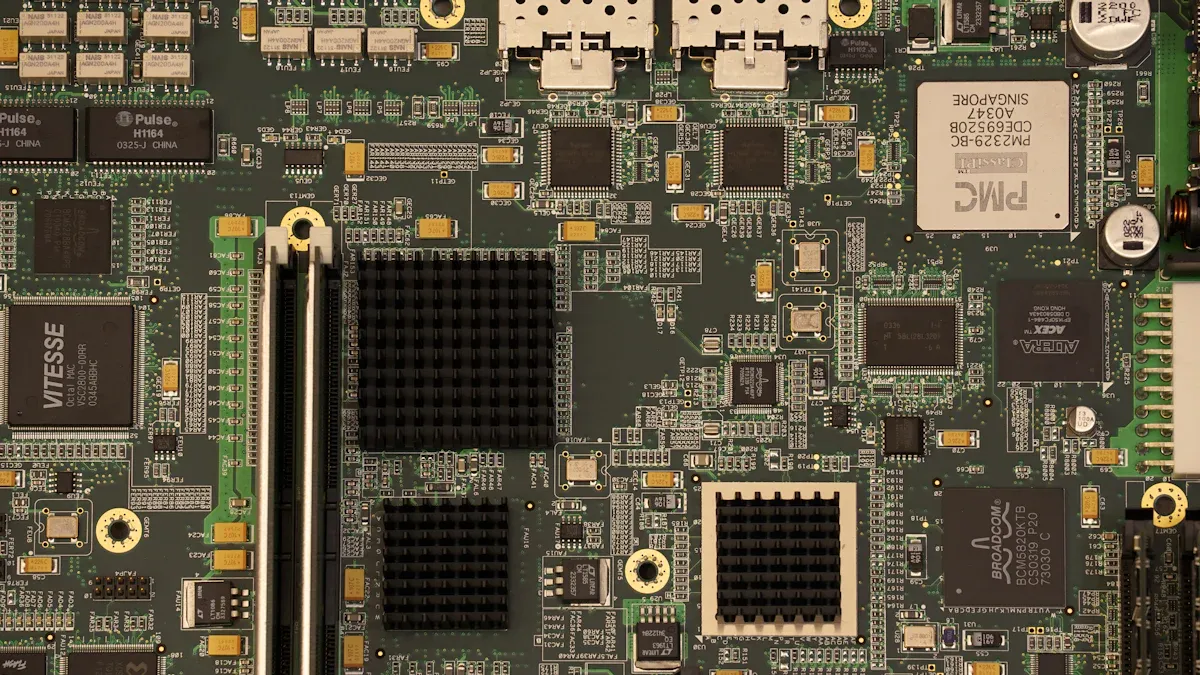

A system on module uses the idea of SoC but adds more. It puts a whole system on a small board. This board has the SoC, memory, storage, and other hardware. SoM connects to a bigger board called a carrier board. The carrier board holds extra things like connectors or power supplies. SoM helps engineers build new products faster. They do not have to design every part from the beginning.

SoC puts many parts in one chip, but SoM gives a ready-to-use module with more hardware.

Here is a simple comparison:

| Feature | SoC (System on Chip) | SoM (System on Module) |

|---|---|---|

| Integration | Processor, memory, I/O on one chip | SoC plus memory, storage, and more hardware |

| Physical Form | Single silicon chip | Small board with multiple chips and parts |

| Included Components | CPU, GPU, memory controller, I/O | SoC, RAM, flash, power, Ethernet, RTC, etc. |

| Flexibility | Fixed hardware, less flexible | More flexible, easy to upgrade or change |

| Development Effort | High, needs custom board design | Lower, ready-to-use for faster projects |

Integration and Flexibility

Integration means how many parts work together in one chip or module. SoC puts the processor, memory, and input/output on one chip. This makes devices smaller and more efficient. For example, the AMD Zynq 7000-series SoC has a dual-core ARM Cortex-A9 running up to 1000 MHz and FPGA logic. This chip can do many jobs at once and uses less power.

SoM adds even more hardware to the module. A normal SoM has the SoC, DDR3 SDRAM, NAND flash, quad SPI flash, Gigabit Ethernet PHY, and a real-time clock. The module can have up to 178 user input/output pins. These pins can be SPI, SDIO, CAN, I2C, UART, USB 2.0, PCIe Gen2 x4, and Gigabit Ethernet. This whole system fits on a board as small as 56 × 54 mm. SoM also uses special DC/DC converters to keep power use low.

SoM is more flexible than just SoC. Engineers can choose a SoM that fits their needs and connect it to a custom carrier board. This lets them change or upgrade hardware without making a new system. SoM also helps lower cost and risk. Teams can use ready Linux software and toolchains, which helps them finish faster.

-

SoC: Good for products that need a small, low-power chip with fixed hardware.

-

SoM: Good for projects that need a full system, fast design, and easy upgrades.

System on Chip (SoC)

SoC Features

A system on chip puts many computer parts into one chip. This chip usually has a central processing unit, memory, and controls for input and output. Sometimes, it also has a graphics processing unit. SoC designs help make devices smaller and use less energy. Many embedded systems use SoC because it saves space and power.

Some important features of SoC are:

-

High reliability and quality, checked by rules like AEC-Q100.

-

Functional safety, helped by ISO 26262, to stop problems.

-

Security and long-lasting use, needed for cars and medical tools.

-

Hardware acceleration, using GPU, FPGA, or ASIC for better speed.

-

Power management, like changing voltage and speed to save energy.

-

Software optimization, such as checking code and picking the right operating system.

SoC performance depends on a few key things. The table below shows what these things mean for embedded systems:

| Performance Metric | Definition | Importance in SoC Embedded Systems |

|---|---|---|

| Latency | Time delay between asking for and getting data | Very important for fast and real-time work |

| Bandwidth | Most data that can move at once | Needed for quick data work and moving lots of data |

| Accuracy | How correct and steady data moves | Needed for safe and stable systems |

A special part inside the chip can watch how data moves and is used. This helps engineers use resources better and make the system work well. It is very helpful for high-speed computing and real-time jobs.

SoC Applications

SoC technology is used in many new devices. These chips are in smartphones, tablets, wearables, and car systems. In embedded systems, SoC lets devices process data fast and react quickly. For example, wearables use SoC to track health, check vital signs, and help find diseases. Studies show 22.3% of research on wearables links device data to health results. Also, 17.3% uses wearables to watch special groups.

Other uses are smart home devices, factory machines, and medical tools. SoC chips help when fast work, accuracy, and trust are needed. In cars, SoC helps with safety and driver help features. In communication, SoC gives fast and steady connections.

The chip can do hard jobs quickly, so it is great for embedded uses that need speed and efficiency. SoC keeps helping new ideas in many areas, making it very important in today’s technology.

System on Module (SoM)

SoM Features

A system on module gives a full way to build smart devices. Engineers use SoM to put a processor, memory, storage, and other parts on a small board. This board connects to a carrier board. The carrier board adds things like connectors and power supplies. The SoM design makes building faster and easier. Teams do not have to make every part from the start. They can use tested modules, which means fewer mistakes and saves time.

SoM works in many embedded applications. It is good for systems that need fast data and real-time work. The SoM design also helps companies spend less money. Using modular hardware lets teams change things without starting over. SoM solutions make systems more reliable. The hardware modules are tested well, so the system works longer and needs less fixing.

Recent market data shows SoM helps many kinds of companies. For example:

-

Simple design makes things less confusing

-

Real-time applications work better

-

Lower costs by skipping long design steps

-

Easy to grow or reuse for new needs

-

Works with many operating systems

SoM Flexibility

Flexibility is a big benefit of the SoM design. SoM lets engineers change or upgrade hardware easily. They can swap modules or add features without making a new system. This helps many uses, like factory machines or medical tools.

Studies show flexible work and design make people happier and get better results. SoM lets teams change things fast. The SoM design makes it easy to customize, which is important for different needs. Better reliability and easy fixing come from this flexible way. SoM works with many software types, so it is a good choice for fast-changing markets.

The world market for SoM keeps growing. Companies in North America, Europe, and Asia Pacific use SoM for cars, factories, and smart tech. The SoM design helps these industries keep up with new technology and digital changes.

SoC and SoM Comparison

Development and Cost

Development effort and cost are important when picking between system on chip and system on module. SoM is easier for engineers because it uses hardware that is already tested and put together. This helps teams finish their work faster and make fewer mistakes. SoM also costs less to develop since companies can buy ready-made modules and use them in different products. Many SoMs are already certified, so teams save time and money when checking rules.

SoC needs more work. Engineers must design special hardware and put many parts together. This takes more time and costs more at first. If something goes wrong, fixing it can be expensive. But SoC is cheaper for making lots of devices. The cost for each device goes down when companies make many of them because the chip design is shared.

Here is a quick comparison:

| Aspect | System on Module (SoM) | System on Chip (SoC) |

|---|---|---|

| Development Effort | Lower, uses pre-integrated hardware | Higher, needs custom hardware design |

| Initial Development Cost | Lower, pre-designed modules | Higher, custom design and debugging |

| Time-to-Market | Faster, less hardware complexity | Slower, more integration work |

| Per-Unit Production Cost | Higher, module markup | Lower at high volumes |

| Certification | Often pre-certified | Needs full certification |

| Suitability | Best for rapid prototyping, low-to-mid volume | Best for high-volume production |

Tip: SoM is good for new companies or teams that need fast results. SoC is better for companies that want to make thousands or millions of devices.

Performance and Scalability

Performance and scalability are important for many projects. SoC gives high performance because all the hardware is on one chip. This makes data move fast, uses less power, and has less delay. SoC is great for things like smartphones or smart watches that need to work fast. The small size also helps when there is not much space.

SoM gives good performance with strong hardware, but it may not be as fast as a custom SoC. SoM has many hardware parts on a small board, so it can use more power. But SoM is very easy to upgrade. Teams can change or add new hardware quickly. This is helpful when project needs change or new features are wanted.

Here is a side-by-side look:

| Metric | System on Module (SoM) | System on Chip (SoC) |

|---|---|---|

| Performance | Good, flexible hardware, suitable for many uses | High performance, low power, low latency |

| Scalability | Highly scalable, easy to upgrade hardware | Less scalable, hard to upgrade |

| Power Consumption | Higher, due to multiple hardware components | Lower, thanks to integrated hardware |

| Maintenance | Easier, swap modules for upgrades | Harder, chip-level changes needed |

| Form Factor | Larger, modular design | Smaller, single chip |

Note: SoM is flexible and easy to upgrade. SoC gives the best speed and power use for designs that do not change.

If a project needs the fastest speed and best power use, SoC is the best. If a team wants to change things quickly and fix things easily, SoM is a better choice.

Choosing the Right Solution

Project Requirements

Picking between a system on chip and a system on module depends on what the project needs. Teams should think about their goals, what kind of product they want, and what problems they might face. Reports say that good projects follow steps like these: First, teams decide what business questions they want to answer and pick the best data sources. Next, they try to avoid mistakes by using trusted hardware and good ways to look at data. Then, they build the system by picking what things to measure and making programs. After that, they run the system and write down what happens, making sure to keep track of every step.

Checking for risks is very important. Teams need to make sure data is correct, private, and follows the rules. Some frameworks, like GAMP® 5, help teams check if their tools and steps are good. A good plan for handling data keeps it safe and trustworthy. This means using passwords, locking data, and writing down what happens. How much checking is needed depends on how risky and hard the project is. In some jobs, like medicine, it is most important to keep track of everything and follow the rules.

Reports also say it is smart to use advice based on facts. These reports help teams set goals and know what to measure for their type of work. By following these ideas, teams can make better choices and not make common mistakes when building embedded systems.

Design and Support

How a team designs a product changes how easy it is to build, fix, or upgrade it. SoM gives teams hardware that is already put together, so they can finish faster. This way, teams do not have to design every board or test every part. They can spend more time working on software and new features.

SoC lets teams control the hardware more. This is good for products made in large numbers that need special parts. But this choice often takes more time and money. Getting help is important too. Many SoM sellers give help for a long time, send updates, and share guides. This makes it easier for teams to keep their products working well. With SoC, teams might need their own experts to fix problems and update things.

Tip: Teams should pick hardware that matches what they know, how much money they have, and what they want in the future. Good help and clear guides make it easier to fix and upgrade products later.

Real-World Applications

Consumer Devices

System on chip and system on module are used in many devices. Phones, tablets, and smartwatches use SoC for fast speed and low battery use. SoM helps companies make smart speakers and streaming devices quickly. In 2023, the world market for SoM was about USD 1.20 billion. Experts think it will reach almost USD 1.95 billion by 2029. This means more companies are using SoC and SoM in electronics. These small and easy-to-use solutions help brands make new products faster. Many companies pick SoM to finish projects quickly and make fewer mistakes.

Industrial and IoT

Factories and smart buildings use SoC and SoM for many jobs. SoC gives strong power for machines that run all day. SoM is flexible for projects that change a lot. Engineers use SoM to build control panels and sensors for the Internet of Things. These modules help connect machines and send data to the cloud. SoM makes it simple to upgrade hardware when new features are needed. In factories, SoM helps teams save time and money by reusing tested parts. This way is more reliable and helps keep up with new technology.

Automotive and Medical

Cars and medical tools need safe and trusted systems. SoC runs many car features like driver help and safety controls. Medical devices use SoM for patient monitors and portable tools. SoM lets engineers update hardware fast when new rules come out. Both SoC and SoM give high speed and real-time response, which are important in these fields. Companies trust these technologies because they meet strict safety and quality rules.

Note: SoC and SoM are important in many areas. They are used in everyday gadgets and in medical tools that save lives.

Picking between a system on chip and a system on module depends on what the project needs. Some things to think about are how easy it is to change, how much it costs, and if you can upgrade it later. The table below shows the main differences:

| Feature | SoC (System-on-Chip) | SoM (System-on-Module) |

|---|---|---|

| Flexibility | Low | High |

| Development Time | Longer | Shorter |

| Upgrade Path | Difficult | Easier |

Teams need to pick what fits their goals best. If a project is tricky or might change, SoM helps teams finish faster and upgrade easily. If a team wants to make lots of the same thing, SoC is a better choice. Teams can also talk to hardware experts or look at real-life examples to help them decide.

FAQ

What is the main difference between SoC and SoM?

A system on chip (SoC) combines key components on one chip. A system on module (SoM) places a SoC and extra hardware on a small board. SoM offers more flexibility for upgrades.

Can engineers upgrade a SoM more easily than a SoC?

Yes. Engineers can swap or upgrade a SoM without changing the whole system. SoC upgrades often require a new chip design, which takes more time and money.

Which is better for fast product development?

SoM works best for quick development. Teams use pre-built modules, which saves time and reduces errors. SoC needs more custom work, so projects take longer.

Are SoC and SoM both used in medical devices?

Yes. Medical devices use both. SoC helps with small, low-power tools. SoM supports devices that need easy upgrades and long-term support, like patient monitors.

Written by Jack Elliott from AIChipLink.

AIChipLink, one of the fastest-growing global independent electronic components distributors in the world, offers millions of products from thousands of manufacturers, and many of our in-stock parts is available to ship same day.

We mainly source and distribute integrated circuit (IC) products of brands such as Broadcom, Microchip, Texas Instruments, Infineon, NXP, Analog Devices, Qualcomm, Intel, etc., which are widely used in communication & network, telecom, industrial control, new energy and automotive electronics.

Empowered by AI, Linked to the Future. Get started on AIChipLink.com and submit your RFQ online today!