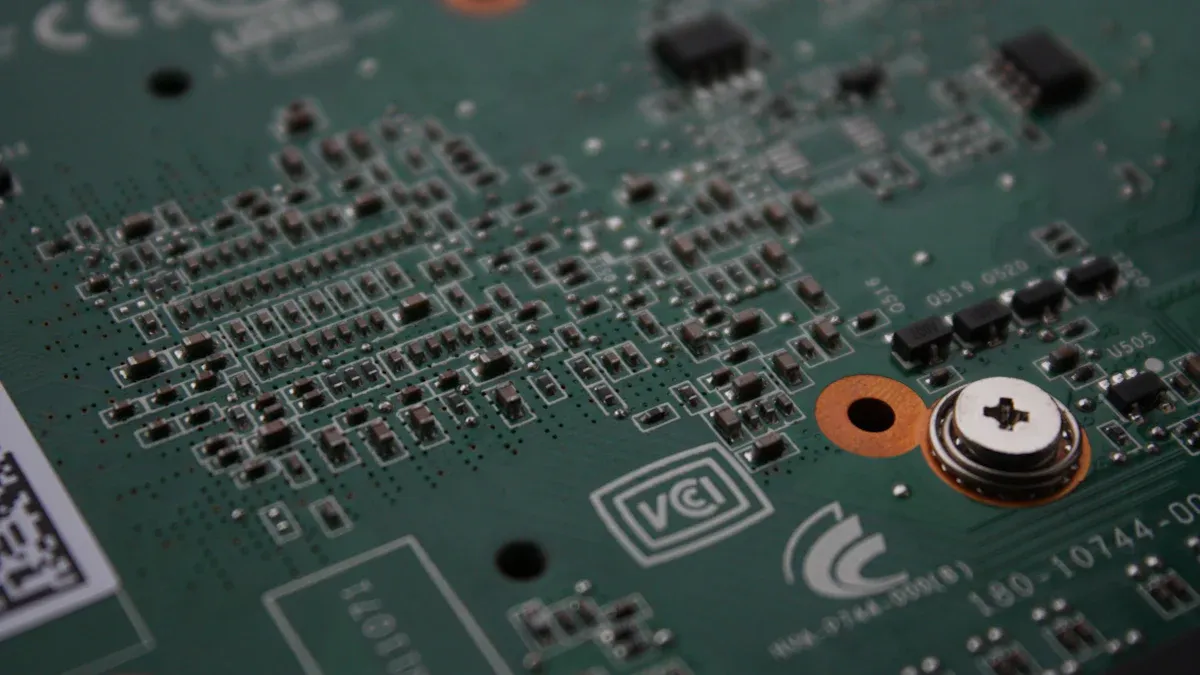

You often see a SOP package when you look inside modern electronic devices. This compact, surface-mount IC package helps you connect integrated circuits directly to printed circuit boards. Surface-mount technology has changed the way you build electronics. Machines can now place more than 136,000 components every hour, making devices smaller and faster. The table below shows some impressive facts about this technology:

| Statistic Description | Numerical Value / Detail |

|---|---|

| Placement speed of SMT machines | More than 136,000 components/hour |

| Market penetration by 1986 | 10% of the market |

| Smallest SMT package sizes as of 2024 | Down to 006003 |

A SOP package plays a key role in making your gadgets more powerful and reliable.

Key Takeaways

-

SOP packages save space by mounting chips directly on circuit boards, making devices smaller and lighter.

-

Their design with gull wing leads and compact shape speeds up automated assembly and improves reliability.

-

Different SOP types fit various needs, balancing size, heat management, and pin count for many applications.

-

Compared to older packages like DIP, SOP offers better performance, smaller size, and easier manufacturing.

-

SOP packages power many devices from smartphones to industrial machines, supporting faster, cooler, and more reliable electronics.

SOP Package Basics

Definition

You often see the SOP package in many modern electronic devices. SOP stands for Small Outline Package. This type of integrated circuit packaging is designed for surface mounting on printed circuit boards. The SOP package has a thin, compact shape. This design helps you save space on the board and supports the trend of making electronics smaller and lighter.

You can find SOP packages with different numbers of pins. Some have as few as four pins, while others have up to thirty-two. Each pin count fits a specific need, from simple parts like diodes to complex chips used in smartphones or cars. You will notice SOP packages in many products, such as tablets, routers, medical equipment, and even in cars for navigation or safety systems. The popularity of the SOP package comes from its ability to fit into tight spaces and its support for automated assembly lines.

Note: SOP packages help you use space wisely and make your devices more reliable.

Core Function

The main job of the SOP package is to connect the tiny circuits inside a chip to the rest of your device. It does this by letting you mount the chip directly onto the surface of the circuit board. This method is called surface-mount technology. You do not need to push the chip through holes in the board, which saves time and makes assembly easier.

Here are some key functions and benefits of the SOP package:

-

You can fit more components on a single board because of the compact size.

-

Surface-mount design lets machines place chips quickly and accurately, which speeds up production.

-

The package helps move heat away from the chip, so your device stays cool and lasts longer.

-

SOP packages reduce unwanted electrical effects, which keeps signals clear and fast.

-

Standard shapes and sizes make it easy for you to swap parts or design new products.

-

Different pin counts give you flexibility for simple or complex circuits.

You will find that the SOP package supports high-speed and high-frequency uses. It also helps you build devices that are smaller, lighter, and more powerful. The design of the SOP package makes it a favorite in many industries, from consumer gadgets to medical and automotive systems.

SOP Package Structure

Physical Form

When you look at a SOP package, you notice its rectangular body. This shape is not random. Engineers use advanced 3D scanning and shape analysis to make sure the package fits well on circuit boards. Most SOP packages have a body that is wider than it is tall, which helps you save space on your device. The rectangular design also makes it easy for machines to place the package during assembly.

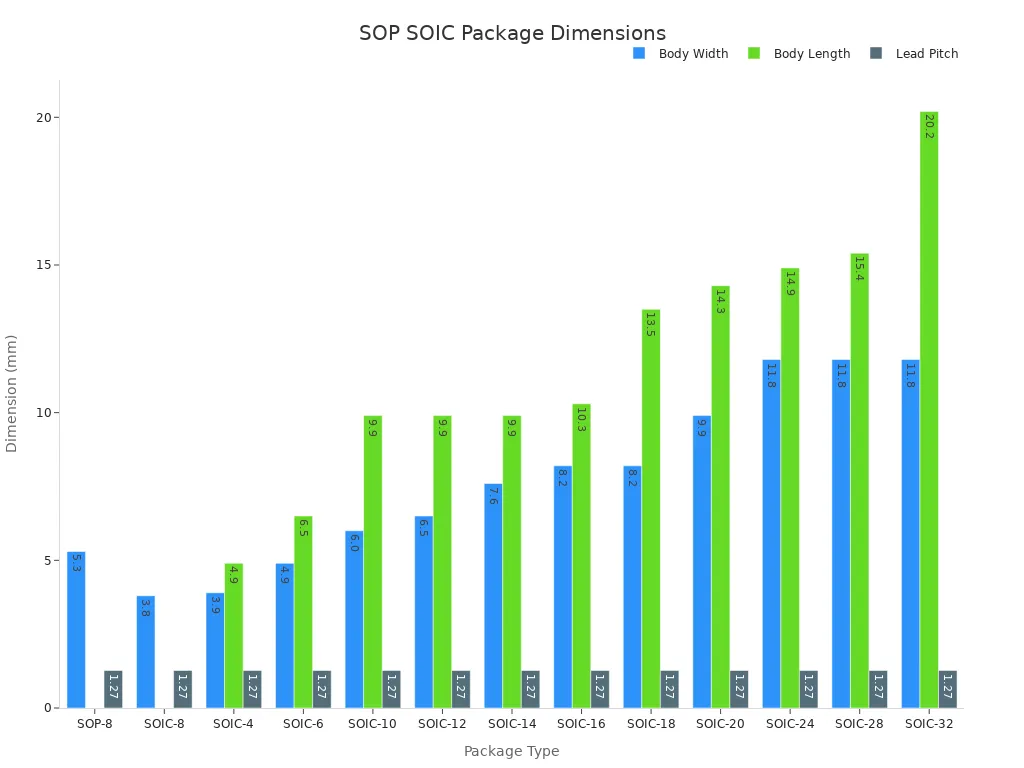

You can see the typical dimensions for different package types in the table below:

| Package Type | Body Width (mm) | Body Length (mm) | Lead Pitch (mm) |

|---|---|---|---|

| SOP-8 | 5.3 | N/A | 1.27 |

| SOIC-8 | 3.8 | N/A | 1.27 |

| SOIC-4 | 3.9 | 4.9 | 1.27 |

| SOIC-6 | 4.9 | 6.5 | 1.27 |

| SOIC-10 | 6.0 | 9.9 | 1.27 |

| SOIC-12 | 6.5 | 9.9 | 1.27 |

| SOIC-14 | 7.6 | 9.9 | 1.27 |

| SOIC-16 | 8.2 | 10.3 | 1.27 |

| SOIC-18 | 8.2 | 13.5 | 1.27 |

| SOIC-20 | 9.9 | 14.3 | 1.27 |

| SOIC-24 | 11.8 | 14.9 | 1.27 |

| SOIC-28 | 11.8 | 15.4 | 1.27 |

| SOIC-32 | 11.8 | 20.2 | 1.27 |

Lead Design

You will see that SOP packages use "gull wing" leads. These leads stick out from the sides and then bend down, looking like a bird’s wings. This design helps you solder the package directly onto the surface of the circuit board. The leads have a standard pitch, usually 1.27 mm, which means the distance from the center of one lead to the next is always the same. This regular spacing makes it easier for machines to place and solder the package quickly and accurately. The gull wing shape also helps you inspect the solder joints after assembly.

Substrate Role

The substrate sits at the heart of every SOP package. It holds the chip in place, connects the chip to the leads, and helps move heat away from the chip. You can find different types of substrates, such as ceramic, copper, or flexible polymers. Each type offers a balance between thermal management and mechanical support.

-

Rigid substrates like ceramic bonded to copper (DBC) give you strong support and good heat flow, but they can crack if the temperature changes too much.

-

Flexible substrates can bend without breaking, which is great for wearable devices, but they do not move heat as well as rigid ones.

-

Newer substrates use thick metal layers or special bonding to improve both heat flow and strength.

Tip: The right substrate helps your device last longer by keeping the chip cool and safe from bumps or drops.

The substrate also acts as the main electrical path between the chip and the board. Advances in substrate technology, such as thicker metal layers and better bonding, help you build devices that run cooler and work more reliably.

SOP Package Types

When you explore the world of surface-mount devices, you will find several types of SOP package. Each type offers unique features that help you match the right package to your project.

PSOP

PSOP stands for Plastic Small Outline Package. You will often use this type when you need extra features, such as a heat sink pad. The heat sink pad helps you move heat away from the chip. This makes PSOP a good choice for power management chips or memory devices. You will notice that PSOP packages look similar to standard SOP, but they have a thicker body and sometimes a metal pad underneath.

Tip: If your circuit gets hot, you should consider PSOP for better cooling.

TSOP

TSOP means Thin Small Outline Package. You will see TSOP used in memory chips, like DRAM or flash memory. TSOP has a thinner body and more pins than standard SOP. The leads stretch out from the sides in a gull wing shape, but the package sits closer to the board. This design helps you save space and fit more chips on a single board.

-

TSOP is popular in laptops, cameras, and other compact devices.

-

You can use TSOP when you need high pin counts and low profile.

TSSOP

TSSOP stands for Thin Shrink Small Outline Package. You will find TSSOP even smaller than TSOP. The leads are closer together, and the body is very thin. TSSOP works well for circuits that need many connections but have little space. You will see TSSOP in audio devices, controllers, and sensors.

| Package Type | Body Thickness | Lead Pitch | Common Uses |

|---|---|---|---|

| PSOP | Thick | 1.27 mm | Power, memory chips |

| TSOP | Thin | 0.5-0.8 mm | Memory, storage |

| TSSOP | Very thin | 0.65 mm | Audio, controllers |

You can choose the right SOP package type by looking at your space, heat, and pin needs.

SOP Package vs Other IC Packages

SOP vs DIP

You often see DIP, or Dual In-line Package, in older electronics. DIP uses two rows of pins that go through holes in the circuit board. You must solder these pins by hand or with a machine. The SOP package, on the other hand, sits flat on the board. Machines place it directly on the surface, which saves time and space.

Here is a table to help you compare:

| Feature | DIP (Dual Inline Package) | SOP (Small Outline Package) |

|---|---|---|

| Package Type | Through-hole | Surface-mount |

| Pin Arrangement | Two parallel rows, 2.54 mm apart | Two rows of gull-wing leads |

| Assembly Method | Manual insertion and soldering | Machine placement and soldering |

| Physical Size | Larger, long pins | Smaller, compact footprint |

| PCB Impact | Needs holes, more complex board | No holes, simpler board |

| Application Suitability | Prototyping, repair, low volume | High-density, mass production |

| Signal Performance | Longer leads, more noise | Short leads, better signal |

You will notice that the SOP package is the surface-mount version of DIP. It lets you build smaller, faster, and more reliable devices.

SOP vs SOIC

SOIC stands for Small Outline Integrated Circuit. It looks similar to the SOP package, but there are some differences. SOIC usually has a standard lead pitch of 1.27 mm, while SOP can have a range of lead pitches, sometimes even smaller. Both use surface-mount technology, but SOIC leads are thinner and shaped like gull wings to save space.

| Feature | SOP Package | SOIC Package |

|---|---|---|

| Lead Pitch | 0.4 - 2.54 mm (varies by type) | Typically 1.27 mm |

| Lead Shape | L-shaped or gull-wing | Gull-wing |

| Thickness | Generally thicker | Thinner profile |

| Mounting Technique | Surface-mount | Surface-mount |

| Variants | Many (SSOP, TSOP, TSSOP) | Narrow and wide body |

You can use both SOP and SOIC on the same board because their sizes are similar. SOP gives you more options for lead pitch and thickness.

SOP vs QFP

QFP, or Quad Flat Package, has leads on all four sides. This design lets you connect more pins, which is great for complex chips. The SOP package only has leads on two sides, so it fits well in smaller devices.

| Package Type | Lead Pitch (mm) | Pin Count | Thickness (mm) | Description | Advantages / Disadvantages |

|---|---|---|---|---|---|

| SOP | 0.4 - 2.54 | 8 - 64 | 0.63 - 12.96 | Leads on two sides | Saves space, fewer pins |

| QFP | 0.4 - 1.0 | 32 - 256 | 1.0 - 2.0 | Leads on four sides | More pins, larger size |

You should choose QFP if you need many connections, like in microcontrollers. If you want a compact design, the SOP package works better. Both use surface-mount technology, which helps you build smaller and faster devices.

Tip: SOP packages help you save board space and make assembly easier, while QFP gives you more pins for complex circuits.

SOP Package Applications

Consumer Electronics

You see SOP packages everywhere in consumer electronics. These packages help make your devices smaller, lighter, and more powerful. You find them in smartphones, smartwatches, gaming consoles, and even smart home devices. Companies use SOP packages because they save space and lower costs while improving performance. The demand for miniaturized and multifunctional devices keeps growing, especially with the rise of IoT and 5G.

| Aspect | Details |

|---|---|

| Market Size & Growth | Global multichip package market projected to reach USD 27.6 billion by 2023, CAGR 11.2% |

| Key Market Segments | Consumer electronics expected to hold the largest share in 2023 |

| SOP Segment Growth | System-on-Package (SoP) segment expected to grow at the fastest CAGR |

| Consumer Electronics Devices | Smartphones, wearable devices, gaming consoles |

You notice that Asia-Pacific leads in manufacturing, with China, Japan, and South Korea at the forefront. Leading companies like Amkor Technology and JCET Group continue to innovate in this area. The global SOP market was valued at $2.3 billion in 2023 and is expected to nearly double by 2032. This growth comes from your need for smaller, smarter devices.

Industrial Uses

You also find SOP packages in many industrial applications. Factories use them in automation systems, robotics, and high-performance computing. These packages help reduce space, improve energy efficiency, and lower production costs. Major players such as Samsung, ASE Group, and Toshiba invest heavily in this technology.

| Evidence Aspect | Details |

|---|---|

| Market Size (2024) | USD 3.5 billion |

| Projected Market Size (2033) | USD 8.2 billion |

| CAGR (2026-2033) | 10.3% |

| Key Application Areas | Industrial Automation, Automotive, Telecommunications, Healthcare |

| Advantages for Industrial Use | Improved performance, reduced space, energy efficiency |

You see the Asia-Pacific region leading in industrial adoption, driven by the need for reliable and efficient electronics. SOP packages help you meet strict safety and performance standards in automotive and healthcare equipment.

Emerging Tech

Emerging technologies rely on SOP packages for integration and performance. You see these packages in artificial intelligence, machine learning, blockchain, and IoT devices. The need for secure, fast, and compact solutions drives this trend.

| Emerging Technology Sector | Growth Statistics and Market Projections |

|---|---|

| Artificial Intelligence (AI) | Global AI software market expected to reach $126 billion by 2025 |

| Machine Learning (ML) | Market projected to grow from $1.03 billion in 2016 to $8.81 billion by 2022 |

| Blockchain | Expected to reach $39.7 billion by 2025, CAGR 67.3% |

| Cybersecurity | Cybercrime costs projected to reach $10.5 trillion annually by 2025 |

You benefit from SOP packages in these sectors because they support high-speed data, advanced security, and integration with cloud computing. As data grows and new applications appear, you will see even more use of SOP packages in the latest tech.

Importance in Modern Electronics

Space Efficiency

You want your devices to be smaller and lighter. The SOP package helps you reach this goal. Its compact shape lets you fit more chips on a single board. You can design thinner phones, lighter laptops, and smaller smartwatches. The rectangular body and gull wing leads save space, so you have more room for extra features or a bigger battery. When you use SOP packages, you help make electronics that fit in your pocket or on your wrist.

Performance

You need your devices to work fast and last long. The SOP package supports this by offering strong electrical connections and good heat management. Engineers test these packages with drop, vibration, and compression tests to make sure they survive real-world use. They also check for moisture and static protection. These tests show that SOP packages keep your electronics safe and reliable.

-

Physical stress tests check for drops and bumps.

-

Barrier tests measure how well the package keeps out water and air.

-

Aging tests predict how long the package will last.

-

Cushioning tests see if the package can absorb shocks.

-

Electrostatic tests make sure static electricity does not harm your device.

You also get better electrical performance and lower costs compared to older packages. SOP packages make it easier to build devices that run cool and handle high speeds.

Manufacturing Benefits

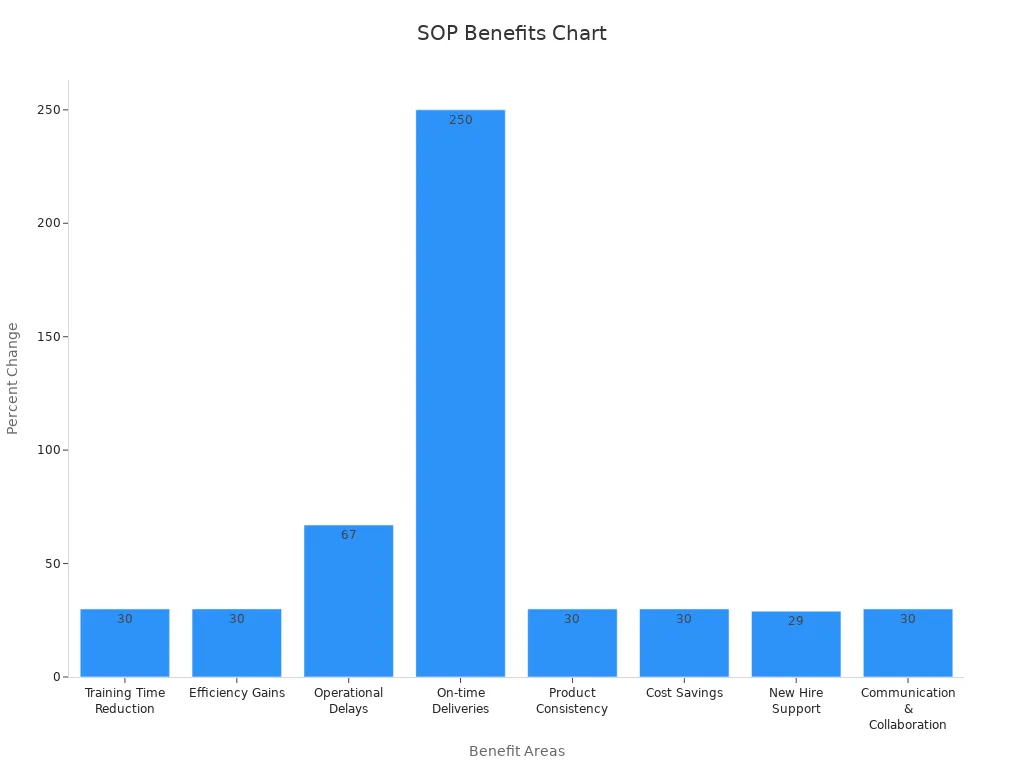

You want products made quickly and with fewer mistakes. SOP packages help factories use lean manufacturing methods. This means less waste and better quality. Studies show that using SOP packages can cut training time by 30% and reduce delays by 67%. You also see up to 30% fewer defects and save money on each product.

| Benefit Area | Statistical Evidence | Impact Description |

|---|---|---|

| Training Time Reduction | 30% reduction | Faster onboarding and more focus on operational excellence |

| Efficiency Gains | Up to 30% improvement from regular SOP reviews | Enhanced operational performance and cost savings |

| Operational Delays | 67% reduction | Smoother production flow and fewer interruptions |

| On-time Deliveries | 250% increase | Significant improvement in meeting delivery schedules |

| Product Consistency | Up to 30% improvement | Reduced defects and variability in products |

| Cost Savings | Up to 30% savings from reduced errors and waste | Lower operational costs and higher profitability |

| New Hire Support | Only 29% feel adequately supported without SOPs | Highlights importance of standardized instructions |

| Communication & Collaboration | 30% rise in collaborative efforts | Better team coordination and reduced miscommunication |

| Digital SOP Benefits | Enhanced accessibility, update speed, and compliance | Faster adaptation and continuous improvement |

Using SOP packages, you help factories build more products, faster and safer. You also make sure each device works the same way every time.

You now understand what an SOP package is and why it matters. This package gives you a compact way to connect chips to your devices. You save space, boost performance, and make assembly easier. When you choose SOP packages, you help create smaller, faster, and more reliable electronics. These benefits make SOP packages vital for today’s technology and the devices you will use in the future.

FAQ

What does SOP stand for in electronics?

SOP stands for Small Outline Package. You use this type of package to mount chips directly onto the surface of a circuit board. It helps you save space and build smaller devices.

How do you identify an SOP package on a circuit board?

You can spot an SOP package by its flat, rectangular shape and gull wing leads on two sides. These leads bend outward and then down, making the package easy to recognize.

Why do you choose SOP packages over DIP packages?

You pick SOP packages when you want to save space and speed up assembly. SOP packages sit flat on the board and let machines place them quickly. DIP packages need holes and take up more room.

Can you use SOP packages for high-speed circuits?

Yes, you can use SOP packages for high-speed circuits. The short leads help reduce electrical noise. This design keeps your signals clear and your devices running fast.

Written by Jack from AIChipLink.

AIChipLink, one of the fastest-growing global independent electronic components distributors in the world, offers millions of products from thousands of manufacturers, and many of our in-stock parts is available to ship same day.

We mainly source and distribute integrated circuit (IC) products of brands such as Broadcom, Microchip, Texas Instruments, Infineon, NXP, Analog Devices, Qualcomm, Intel, etc., which are widely used in communication & network, telecom, industrial control, new energy and automotive electronics.

Empowered by AI, Linked to the Future. Get started on AIChipLink.com and submit your RFQ online today!